OEM Factory for No Core Linear Motor - Top Suppliers Ac Mini Motor Vibration – Leader Microelectronics

OEM Factory for No Core Linear Motor - Top Suppliers Ac Mini Motor Vibration – Leader Microelectronics Detail:

We insist about the theory of growth of ‘High excellent, Performance, Sincerity and Down-to-earth working approach’ to offer you with great company of processing for Top Suppliers Ac Mini Motor Vibration, Our organization quickly grew in size and status because of its absolute dedication to top quality manufacturing, higher value of merchandise and excellent customer assistance.

We insist about the theory of growth of ‘High excellent, Performance, Sincerity and Down-to-earth working approach’ to offer you with great company of processing for Electric Vibration Motor, Mini Motor, Vibrating Motor, Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you’ll be served with good quality consultant service by our after-sale team. They’re about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

SMD/SMT vibration motors are an excellent choice for fully automated, high-speed mass production utilizing pick and place machines. This is the only series of vibration motor available on tape and reel. If hand soldering the motor to the PCB ( i.e. making prototypes), do not use flux as this can enter the motor and cause it to fail. This series of motors cannot be washed after the reflow process.

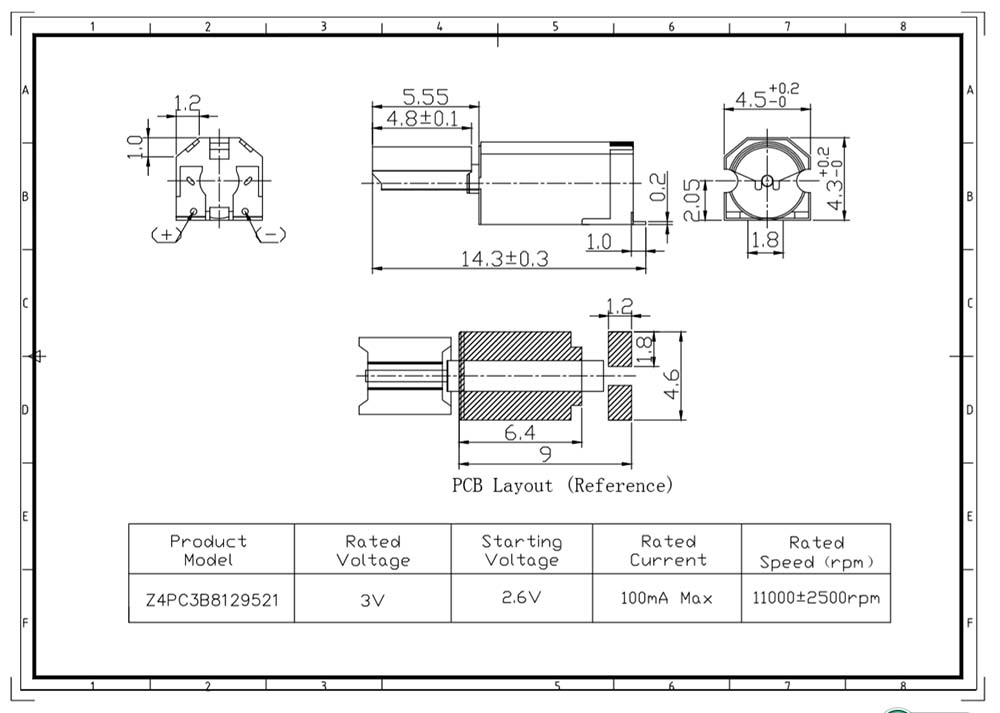

Product Technical Parameters of SMT Phone Vibrating motor:

| Place of Origin | Guangdong, China (Mainland) |

| Model Number | Z4PC3B8129521 |

| Usage | Mobile phone, Watch and Band,Massagers,Medical apparatus and instruments |

| Certification | ISO9001,ISO14001,OHSAS18001 |

| Type | Micro Motor |

| Commutation | Brush |

| Feature | Vibration |

| Rated speed | 11000±2500rpm |

| Rated current | 100 mA Max |

| Starting voltage | 2.6(V) DC Max |

| Rated Voltage | 3.0(V )DC |

| Operating voltage | 2.7~3.3(V )DC |

| Life | 2.5S on,2.5S off, 53,000 cycles |

The main features of Mini SMD Vibrating motor :

These SMD, surface mount vibration motors are packaged on tape / reels of 1000 pieces per reel and are designed to be pick-and-placed directly from the reel.

They are an excellent choice for high volume mass production.

They have a “core” which allows them to withstand the high temperatures associated with the reflow soldering process.

Counterweight can be changed or customized to achieve different vibration force.

Main Export Markets of Our Mini Vibrating Motor:

South Asia: 43%

North America: 27%

Western Europe: 25%

Northern Europe: 5%

The application of Mini High temperature Vibrating motor :

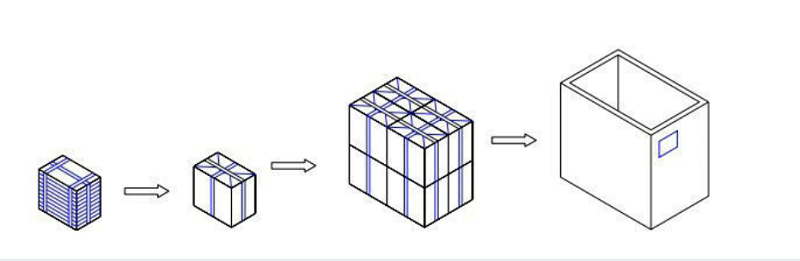

Packaging & Shippment:

1. 50 mini dc drive motors in each PS tray.

2. Every 20 capsules as a group, put a plastic cover on the group and wrap it in tape.

3. Put the wrapped group into a inbox.

4. Every 8 inboxes are put into an outer case by the ways standard as the drawing.

5. Quantity and batch number are written on the surface of the outer case.

Inspection Instrument:

Certificate:

Product detail pictures:

Related Product Guide:

How to Maintain and Repair the Vibrating Motor

Understanding Gear Motors

We always continually provide you with the most conscientious customer service, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for OEM Factory for No Core Linear Motor - Top Suppliers Ac Mini Motor Vibration – Leader Microelectronics , The product will supply to all over the world, such as: New Orleans , Canada , Sacramento , Providing the best products, the most perfect service with the most reasonable prices are our principles. We also welcome OEM and ODM orders.Dedicated to strict quality control and thoughtful customer service, we are always available to discuss your requirements and ensure full customer satisfaction. We sincerely welcome friends to come negotiate business and start cooperation.

Quality Control

We have 200% inspection before shipment and the company enforces quality management methods, SPC, 8D report for defective products. Our company has a strict quality control procedure, which mainly tests four contents as follow:

01. Performance Testing; 02. Waveform Testing; 03. Noise Testing; 04. Appearance Testing.

Company Profile

Established in 2007, Leader Micro Electronics (Huizhou) Co., Ltd. is a high-tech enterprise integrating R&D, production, and sales of micro vibration motors. Leader mainly manufactures coin motors, linear motors, brushless motors and cylindrical motors, covering an area of more than 20,000 square meters. And the annual capacity of micro motors is nearly 80 million. Since its founding, Leader has sold nearly a billion of vibration motors all over the world, which are widely used on about 100 kinds of products in different fields. The main applications conclude smartphones, wearable devices, electronic cigarettes and so on.

Reliability Test

Leader Micro has professional laboratories with a full set of testing equipment. The main reliability testing machines are as below:

01. Life Test; 02. Temperature & Humidity Test; 03. Vibration Test; 04. Roll Drop Test;05. Salt Spray Test; 06. Simulation Transport Test.

Packaging & Shipping

We support air freight, sea freight and express.The main express are DHL, FedEx, UPS, EMS, TNT etc. For the packaging: 100pcs motors in a plastic tray >> 10 plastic trays in a vacuum bag >> 10 vacuum bags in a carton.

Besides, we can provide free samples on request.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!