Arduino Vibration Motors - Custom and High-Quality Solutions for Your Projects

An Arduino Vibration Motor is a compact motor designed specifically for Arduino projects, enabling haptic feedback, alert functions, or dynamic effects. By controlling the current, it generates vibrations and is widely used in robotics, electronic DIY kits, educational devices, and sensor feedback systems. With its small size, low power consumption, and easy integration, it is an ideal choice for makers and engineers.

As a professional manufacturer of Arduino Vibration Motors, Leader brings years of industry expertise and advanced technology to deliver exceptional products. Our motors are crafted with high-quality materials, offering low noise, long lifespan, and high stability to suit diverse applications. Leader also provides comprehensive customization services, including size, power, and vibration frequency, to meet unique customer requirements. With state-of-the-art production facilities and rigorous quality control, we ensure on-time delivery for bulk orders.

Choose Leader for premium quality and unmatched reliability!

Arduino Vibration Motor Technical Specs

Rated Voltage: 1.2 – 3.7VDC (3V typical)

Rated Current: 80mA @ 3V

Still not finding what you're looking for? Contact our consultants for more available products.

Arduino Vibration Motor Strength Control

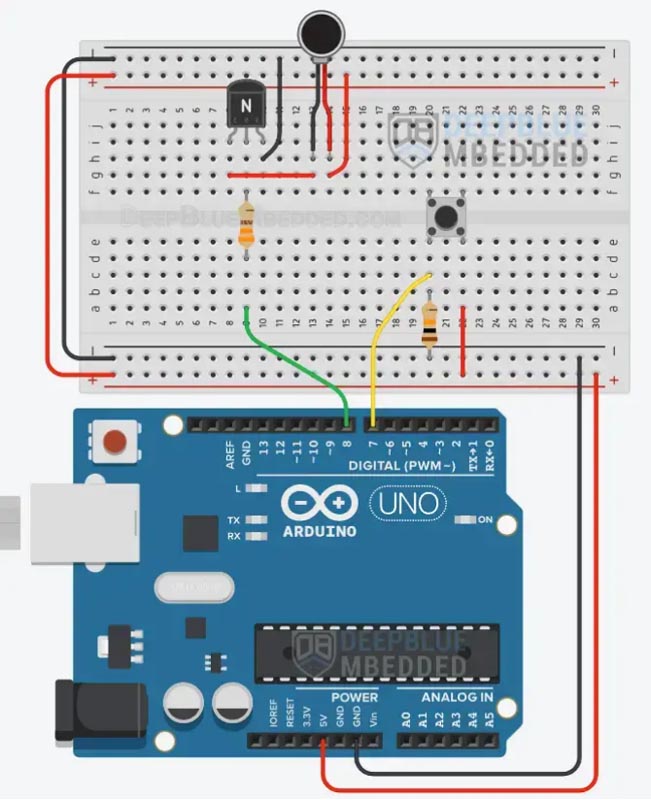

We can use Arduino PWM outputs to control the vibration intensity of a vibration motor. By utilizing a variable duty cycle PWM signal from the Arduino combined with a BJT transistor output driver, we can achieve adjustable vibration intensity on the motor.

When using a PWM signal to control the vibration intensity, it is recommended to connect a Fly-Back Diode in parallel with the vibration motor. This diode will protect the output driver transistor from the inductive spikes generated by the motor.

Arduino Vibration Motor Circuit Diagram

Arduino is a user-friendly development platform that is affordable and supported by a large and active community. Its popularity can be attributed to its simplicity- the microcontroller is integrated directly on the board and all the necessary components required for programming are already included. All you need to do is connect the USB to your computer and download the software.

There are many types of Arduinos for different applications. The most popular one is Arduino UNO R3. However, there is one key limitation to be aware of when using a microcontroller to drive a motor: most DC vibration motors require a starting current and operating current that exceeds the output current capability of the microcontroller pins. That means we need an intermediate component between the microcontroller and the motor. We use the term "component" broadly because there are many options available, including dedicated drivers or haptic feedback chips. To keep this guide simple and easy to understand, we will focus on the use of transistors.

There are 4 basic elements to vibration motor Arduino circuit:

●A microcontroller

●A transistor

●A vibration motor

●A power source

This is the wiring diagram for the vibration motor Arduino control circuit which uses a transistor as the drive switch. It is important to note that the vibration motor is powered by the transistor which receives the 5V DC power from the Arduino UNO board. Alternatively, we can use the 3.3V output pin to run the vibration motor in a lower but safer manner.

How to Drive a Vibration Motor with Arduino

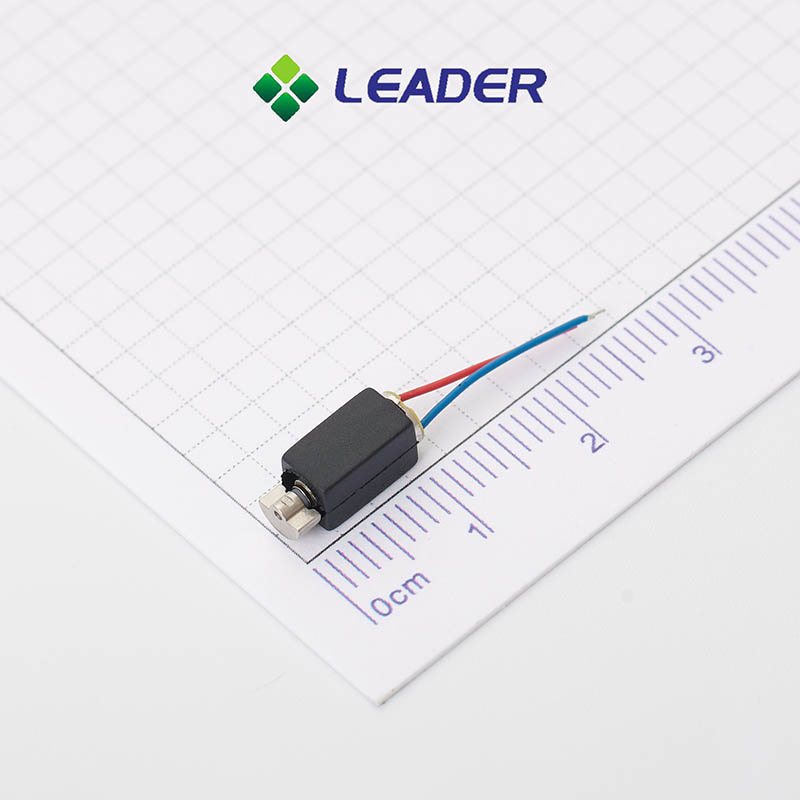

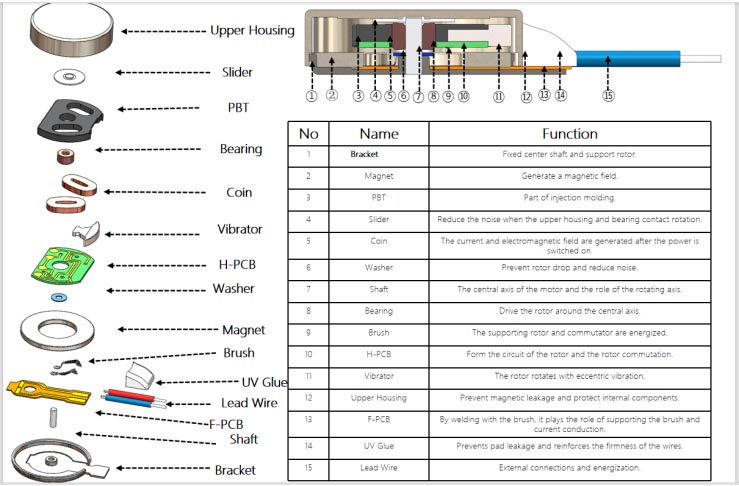

A vibration motor is a compact device that generates mechanical vibration using an electric motor with an unbalanced mass on a drive shaft. It is primarily used in various applications to provide tactile feedback to make the user interface more appealing to the end user.

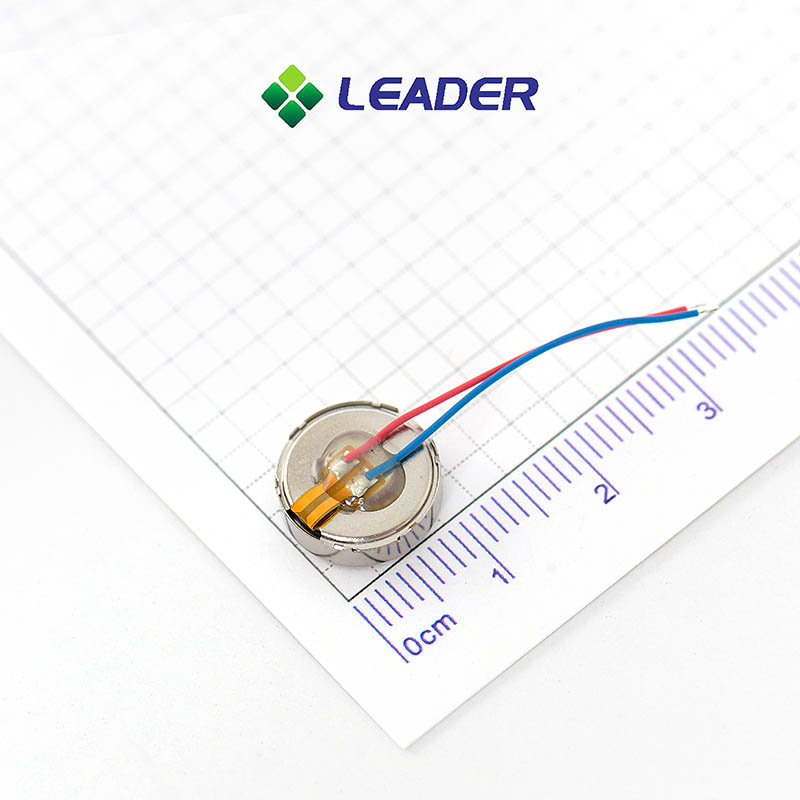

The image above shows the internal structure of a small vibration motor commonly found in mobile phones, similar to the micro-vibration motors used in various Arduino projects. Below is an image of a small vibration motor soldered to a PCB, equipped with a driver transistor control circuit for easy connection to different microcontrollers.

Almost all applications involving vibration motors use microcontrollers. While some industrial applications may require the vibration motor to run continuously (in which case we recommend using a brushless vibration motor), most require the vibration to occur at specific intervals and for a specified duration. As chip costs and sizes drop, it has become very easy to access and integrate microcontrollers into these systems.

How to Choose Mini Vibration Motor Arduino?

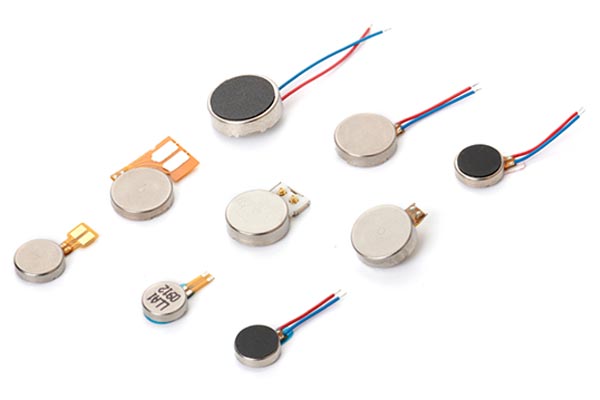

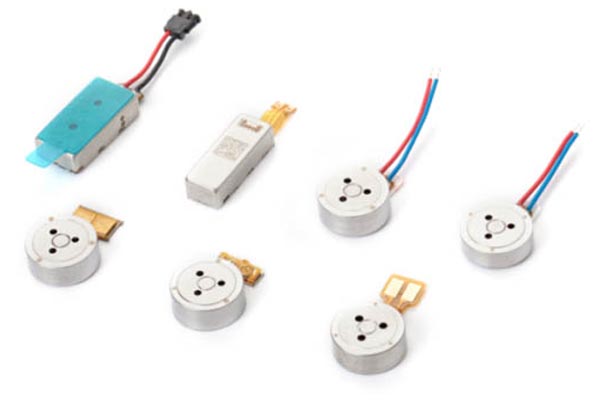

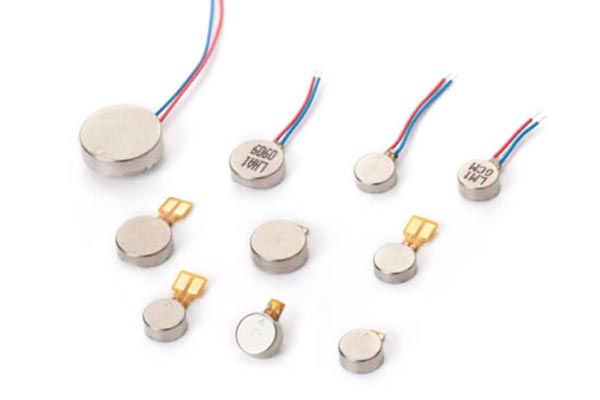

There are different types of vibration motors. We recommend a coin vibration motor arduino. Coin motors are compact and usually used in small devices.

Make sure the voltage and current rating of the motor are compatible with your Arduino board and power supply.

Check the motor's vibration strength specifications, usually in G-force or m/s². Select a motor that meets the vibration strength requirements for your project.

Consider the physical size and weight of the motor, especially if your project has space constraints or requires lightweight.

If you plan to adjust the vibration intensity dynamically, make sure the motor can be easily controlled using a PWM signal.

Check how the motor will be mounted in your project. Some motors come with mounting holes or adhesive backing for easier installation.

Finally, consider your budget and the motors available from your supplier. Look for a reputable brand to ensure quality and reliability.

How to Customize the Arduino Vibration Motor?

Select a vibration motor that meets your project specifications in terms of size, voltage, and vibration intensity.

Use PWM (Pulse Width Modulation) to control the vibration intensity of the motor. This allows you to adjust the duty cycle to change the vibration intensity.

Create a circuit that includes the Arduino, a transistor (or motor driver), and a flyback diode to prevent voltage spikes. Connect the motor to the transistor, which will be controlled by a PWM signal from the Arduino.

Write a program in the Arduino IDE to control the motor. Use the `analogWrite()` function to send a PWM signal to the transistor and adjust the duty cycle to change the vibration intensity.

If necessary, sensors (such as accelerometers) can be included to provide feedback on vibration levels, allowing dynamic adjustments based on real-time data.

Try different mounting techniques or housings to enhance the efficiency of the motor and customize the vibration experience to your needs.

Test your setup and adjust the code, circuit, or physical configuration as necessary to achieve the desired performance.

Why Choose Us as Your Arduino Motor Supplier?

As a Arduino motor supplier, LEADER motor is a reliable factory of vibration motor with arduino. Our products have several main advantages:

We understand that different applications have unique requirements. Therefore, we offer a range of customization options for our vibration motors. Customers can specify parameters such as size, voltage, vibration intensity, and mounting configuration to ensure the motor is perfectly suited to their specific needs. This flexibility allows for customized solutions that improve the performance of your project.

Our vibration motors are designed for long-lasting performance. They are made of high-quality materials and rugged engineering to withstand long-term use in a variety of environments. This durability makes them ideal for applications that require long-term reliable operation, reducing the need for frequent replacement and maintenance.

LEADER's micro-vibration motors operate with very little noise, making them ideal for precision applications. This feature is especially useful in environments such as medical devices, consumer electronics, and other sensitive applications that require quiet operation.

To ensure compatibility and performance, we offer sample testing for our vibration motors. Customers can request samples to evaluate how well the motor will integrate with their system before making a larger commitment. This testing phase helps confirm that our products meet the specific requirements of your application, giving you peace of mind when purchasing.

Looking for reliable micro motors? Explore how our pager motors deliver compact and efficient vibration solutions.

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your coreless motors need, on-time and on budget.