Dia 5mm*2.5mm Small Brushless Motor | DC Vibration Motor| LEADER LBM0525

Main Features

Specification

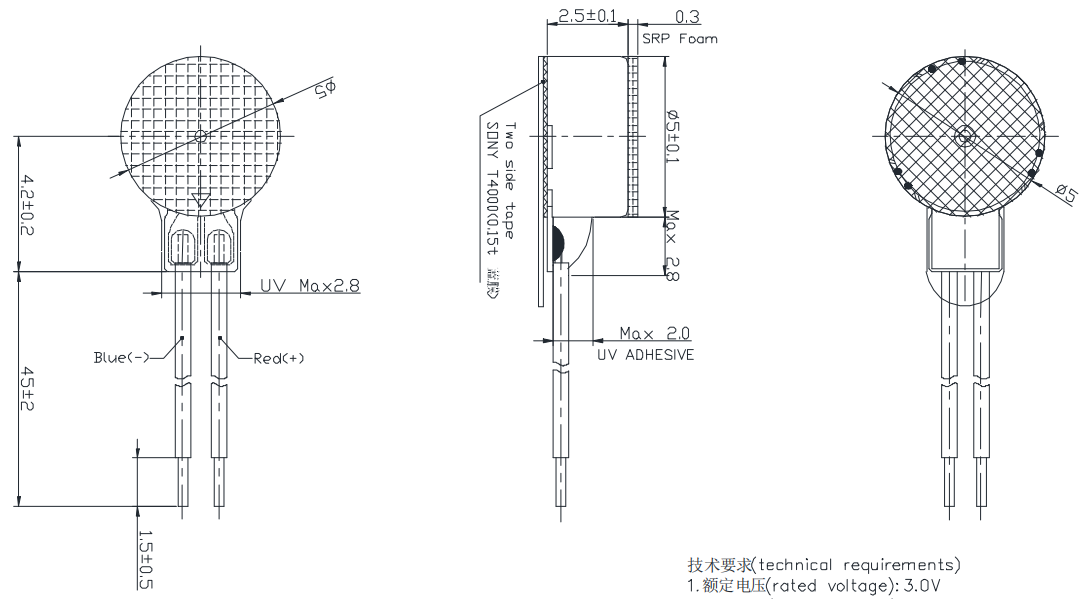

| Technology Type: | BRUSHLESS |

| Diameter (mm): | 5.0 |

| Thickness (mm): | 2.5 |

| Rated Voltage (Vdc): | 3.0 |

| Operating Voltage (Vdc): | 2.7~3.3 |

| Rated Current MAX (mA): | 90 |

| Starting Current (mA): | 175 |

| Rated Speed (rpm, MIN): | 15500±3500 |

| Part Packaging: | Plastic Tray |

| Qty per reel / tray: | 100 |

| Quantity - Master box: | 8000 |

Application

Having a full-wave band IC inside to replace traditional brushes, the brushless motor has stronger vibration force, longer lifetime and even smaller size. The main applications of miniature vibration motor brushless motor are smart watches, medical device, beauty devices, robot, etc.

Working with Us

FAQ For Micro Brushless Motor

The lifespan of micro brushless motor is 500,000 cycles under the condition of 2s on, 1s off.

Answer: This brushless motor can be used with a variety of feedback sensors, including Hall effect sensors.

Answer: Yes, this brushless motor is designed to be highly robust. It can withstand shock and vibration during operation.

Answer: The power consumption of micro brushless motor depends on the specific model and operating conditions, but typically ranges between 0.5W to 1W.

Micro drones often use brushless motors due to their light weight, compact design and higher efficiency. Brushless motors provide more power and longer flight time than brushed motors. The exact size and specifications of the motors may vary depending on the mini drone model and its intended use.

We have succeeded in designing the smallest brushless DC motor to date with a diameter of 6mm and a thickness of 2.5mm. Despite its compact size, the motor has an impressive service life of 500,000 cycles at test mode of 2s On 1s Of. It operates efficiently on direct current (DC) voltage.

Yes,brushless motors are considered superior to brushed motors due to their higher efficiency, longer lifespan, higher power-to-weight ratio, better control and reduced electromagnetic interference. The choice between brushed and brushless motors depends on specific application needs.

Brushless motors is with higher initial cost compared to brushed motors. The technology and construction of brushless motors make them more complex, which can lead to their higher price.

Yes, brushless motors can fail, just like any other mechanical part. Several factors can cause a brushless motor to fail, including overheating, mechanical wear, electrical failure, and insufficient lubrication.

Micro Brushless Motor Manufacturer

A micro brushless motor is a small-sized electric motor that uses brushless technology for propulsion. The motor comprises a stator and a rotor with permanent magnets attached on. The absence of brushes eliminates the friction, resulting in greater efficiency, longer lifespan and quieter operation.A micro brushless motor typically measures less than 6mm in diameter, making it an excellent choice for tiny devices:Especially robots, wearable devices and other micro-mechanical applications where the compact size and high performance are critical.

As a professional micro brushless motor manufacturer and supplier in China, we can meet customers' needs with custom high quality brushless motor. If you are interested, welcome to contact Leader Micro.

Quality Control

We have 200% inspection before shipment and the company enforces quality management methods, SPC, 8D report for defective products. Our company has a strict quality control procedure, which mainly tests four contents as follow:

01. Performance Testing; 02. Waveform Testing; 03. Noise Testing; 04. Appearance Testing.

Company Profile

Established in 2007, Leader Micro Electronics (Huizhou) Co., Ltd. is a high-tech enterprise integrating R&D, production, and sales of micro vibration motors. Leader mainly manufactures coin motors, linear motors, brushless motors and cylindrical motors, covering an area of more than 20,000 square meters. And the annual capacity of micro motors is nearly 80 million. Since its founding, Leader has sold nearly a billion of vibration motors all over the world, which are widely used on about 100 kinds of products in different fields. The main applications conclude smartphones, wearable devices, electronic cigarettes and so on.

Reliability Test

Leader Micro has professional laboratories with a full set of testing equipment. The main reliability testing machines are as below:

01. Life Test; 02. Temperature & Humidity Test; 03. Vibration Test; 04. Roll Drop Test;05. Salt Spray Test; 06. Simulation Transport Test.

Packaging & Shipping

We support air freight, sea freight and express.The main express are DHL, FedEx, UPS, EMS, TNT etc. For the packaging: 100pcs motors in a plastic tray >> 10 plastic trays in a vacuum bag >> 10 vacuum bags in a carton.

Besides, we can provide free samples on request.