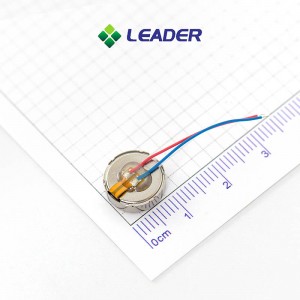

Dia 8mm*2.5mm Coin Type Vibration Motor | LEADER LCM-0825

Main Features

Specification

| Technology Type: | BRUSH |

| Diameter (mm): | 8.0 |

| Thickness (mm): | 2.5 |

| Rated Voltage (Vdc): | 3.0 |

| Operating Voltage (Vdc): | 2.7~3.3 |

| Rated Current MAX (mA): | 80 |

| Starting Current (mA): | 120 |

| Rated Speed (rpm, MIN): | 10000 |

| Vibration Force (Grms): | 1.0 |

| Part Packaging: | Plastic Tray |

| Qty per reel / tray: | 100 |

| Quantity - Master box: | 8000 |

Application

The coin motor has many models to select and it's very ecomonical because of the highly automatic production and the lower labor costs. The main applications of coin vibration motor are smart phones, smart watches, bluetooth earmuffs and beauty devices.

Working with Us

FAQ For Coin Vibration Motor

- CW(clockwise) or CCW(contrary clockwise)

1. Gather necessary equipment: multimeter, power source, and connecting wires.

2. Connect the motor to the power source and multimeter in a closed circuit using the appropriate wires.

3. Set up multimeter to measure DC current on a suitable range for the expected current.

4. Activate the by turning on the power source.

5. Observe the multimeter display to read the current flowing through the motor.

6. Repeat with different power inputs or voltage levels if necessary.

7. off the power source, and safely disconnect the circuit. Ensure that all safety precautions are taken into throughout the process.

Small size makes it easy to mount in or on your project. If mounting onto a PCB, there are often options for soldering via through-hole pins. In the case of Coin and LRAs, you can just use the adhesive backing.

General Layout And Operation

Coin vibration motors (also known as ERM motors) generally have a disc-shaped housing made of metal, with a small motor inside that drives an eccentric weight. Here are the general steps of how a coin vibration motor operates:

1. Power On: When power is applied to the motor, an electrical current flows through the coils inside, creating a magnetic field.

2. Attraction Phase: The magnetic field causes the rotor (eccentric weight) to be attracted towards the stator (coil). This attraction phase moves the rotor closer to the magnetic field, building up potential energy.

3. Repulsion Phase: The magnetic field then switches polarity, causing the rotor to be repelled from the stator. This repulsion phase releases the potential energy, causing the rotor to move away from the stator and rotate.

4. Repeat: The ERM motor repeats this attraction and repulsion phase several times per second, causing rapid rotation of the eccentric weight. This rotation creates a vibration that can be felt by the user.

The speed and strength of the vibration can be controlled by varying the voltage or frequency of the electrical signal applied to the motor. Coin vibration motors are commonly used in devices that require haptic feedback, such as smartphones, gaming controllers, and wearables. They can also be used for alert signals, like notifications, alarms, and reminders.

Quality Control

We have 200% inspection before shipment and the company enforces quality management methods, SPC, 8D report for defective products. Our company has a strict quality control procedure, which mainly tests four contents as follow:

01. Performance Testing; 02. Waveform Testing; 03. Noise Testing; 04. Appearance Testing.

Company Profile

Established in 2007, Leader Micro Electronics (Huizhou) Co., Ltd. is a high-tech enterprise integrating R&D, production, and sales of micro vibration motors. Leader mainly manufactures coin motors, linear motors, brushless motors and cylindrical motors, covering an area of more than 20,000 square meters. And the annual capacity of micro motors is nearly 80 million. Since its founding, Leader has sold nearly a billion of vibration motors all over the world, which are widely used on about 100 kinds of products in different fields. The main applications conclude smartphones, wearable devices, electronic cigarettes and so on.

Reliability Test

Leader Micro has professional laboratories with a full set of testing equipment. The main reliability testing machines are as below:

01. Life Test; 02. Temperature & Humidity Test; 03. Vibration Test; 04. Roll Drop Test;05. Salt Spray Test; 06. Simulation Transport Test.

Packaging & Shipping

We support air freight, sea freight and express.The main express are DHL, FedEx, UPS, EMS, TNT etc. For the packaging: 100pcs motors in a plastic tray >> 10 plastic trays in a vacuum bag >> 10 vacuum bags in a carton.

Besides, we can provide free samples on request.