Leading Haptic Feedback Motors Manufacturer in China | Custom OEM Solutions

Leader, a top Chinese factory, specializes in manufacturing high-quality haptic feedback motors. Our expert team offers custom design and OEM solutions to meet your unique needs, ensuring superior performance and reliability.

Haptic Feedback Vibration Motors by LEADER Motor

Although many smartphone and tablet users are familiar with haptic controllers and notifications, the term "haptic" is fundamentally related to tactile feedback. A common example of haptics is a phone vibrating to signal an incoming call or message. This method can effectively remind users of specific events, attracting their attention through vibration.Discover compact efficiency! Learn how our coin vibration motors deliver powerful performance in a slim, lightweight design!

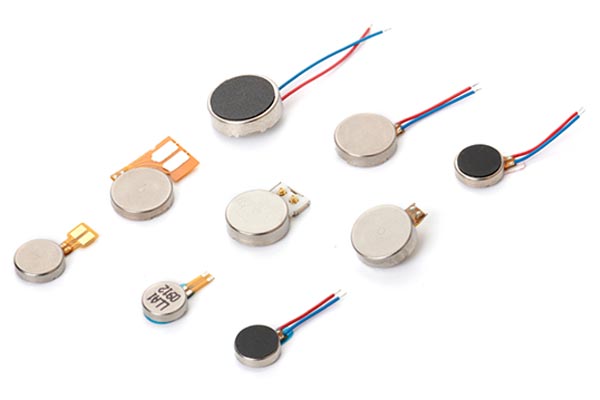

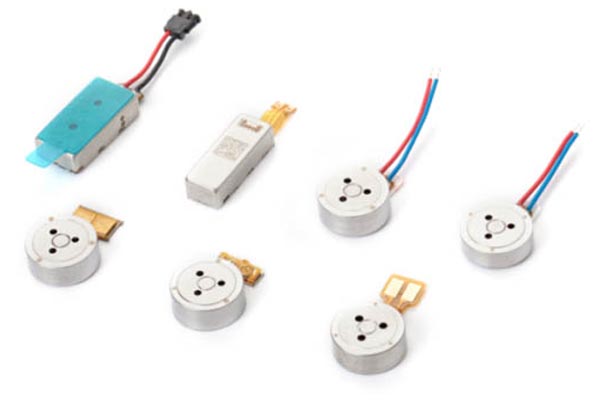

The eccentric rotating mass (ERM) motor and linear resonant actuator (LRA) are two most common types of haptic feedback actuators used in the market today.

Both ERM and LRA haptic motors operate through the interaction of electric and magnetic fields, converting electrical energy into mechanical energy in the form of rotation or vibration. ERM motors produce eccentric rotation by loading a counterweight (eccentric weight) on a shaft or flat configuration, while LRA motors rely on springs to vibrate on a single axis. Variations include Z-axis LRA (vertical direction) and X/Y-axis LRA (horizontal orientation).

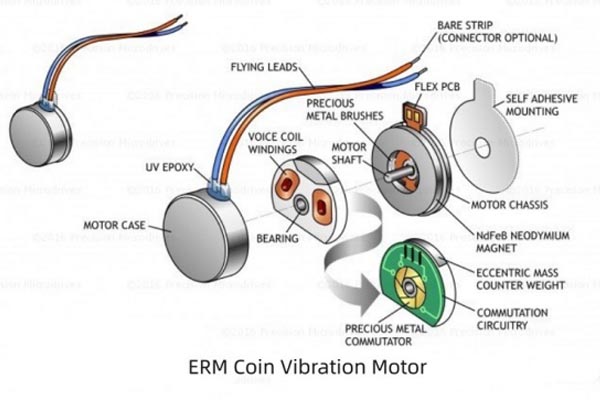

ERM Vibration Motors

An eccentric rotating mass (ERM) is an electric motor with an eccentric rotating mass. As the ERM rotates, the displaced mass creates a "rumble" or vibration feeling.

Because of their low cost, simplicity, and effectiveness, ERMs have long been the most popular type of tactile motor. However, their vibrations lack precision, and their start and stop times can be slow, which limits the range of sensations they can produce.

ERMs are most often found in smartphones, wearables and gaming controllers. They have recently been found in automotive use cases, due to their ability to produce strong and active vibrations.

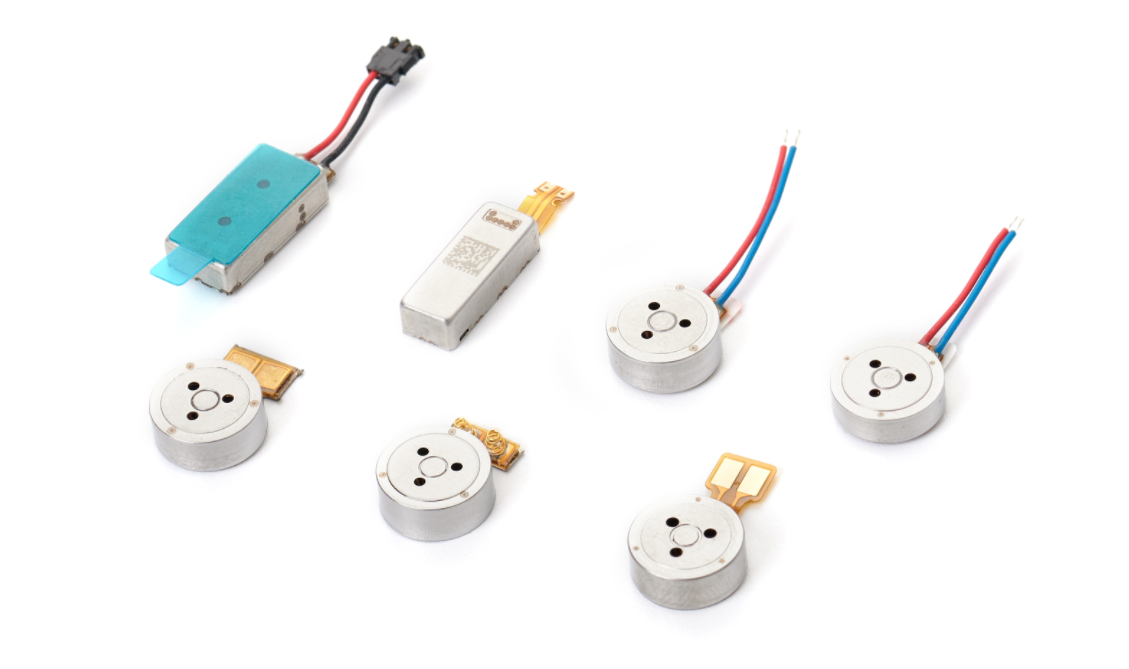

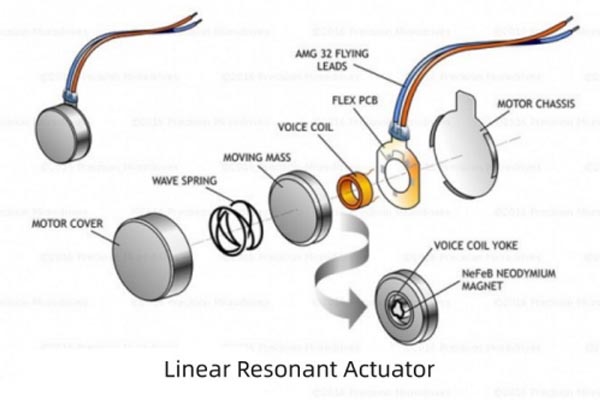

Linear Vibration Motors

LRA motors consist of a magnet attached to a spring, surrounded by an electromagnetic coil and housed in a casing. The coil drives the motor by causing the mass within the housing to oscillate, creating the vibrations we perceive.

Compared to ERM, LRA offers fast response times and efficient power consumption, making it a first choice for devices requiring fast tactile feedback. Still, they are more expensive than ERMs, and the springs are prone to wear.

The widely used LRA motor is Apple's Taptic Engine, which has been integrated into every Apple smartphone starting from iPhone 6s. Following its release in 2015, other smartphone manufacturers have followed the trend by incorporating LRA into their high-end and mid-range models. Currently, most smartphones use LRA instead of ERM to achieve haptic effects.

Still not finding what you're looking for? Contact our consultants for more available products.

Function of Haptic Motor

1. Alert & Notification: Discreetly capture the user's attention with unique tactile effects and vibrations.

2. Button Replacement: Replace traditional controls like buttons, knobs, and switches with tactile feedback and touch input.

3. Touch Screen: Enhance user experience on touch screens and improve safety measures by implementing haptic feedback.

About a third of smartphones include haptic feedback, rather than just a simple vibrating alert. A common example is tactile feedback that simulates a tapping sound when a user types an email or text. Each vibration is used to confirm the recording of a keystroke. The presence of tactile feedback tends to reduce typing errors and lead to a more satisfying user experience.

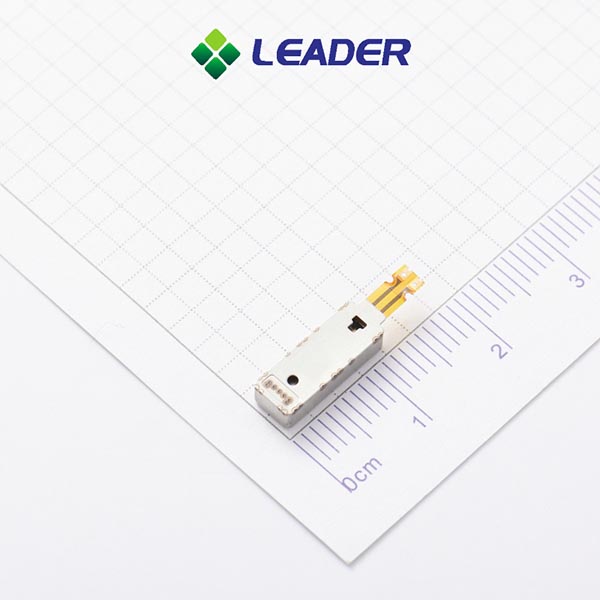

If you are considering integrating haptic controls into your latest product, we are the ideal choice for LRA Haptic Solutions. Our technology provides a more accurate tactile feel with prominent haptic. We offer two types of haptic engines: coin-shaped Z-axis vibration motors and rectangular X-axis vibration motors.

Haptic Vibration Motor A Wide Variety Of Applications

LEADER motor had been developed for over 17 years since 2007. It's using in more and more digital products in our lives. In addition to traditional digital Products, new applications of LEADER micro motor is also continually expanding.

Apply to Apple Touch Screen for Haptic Force Feedback

It aims to enhance the user experience by providing tactile sensations during touch interactions with the screen.

Apply to a Handheld Radio for Vibrating Alarms

The purpose is to provide an alternative to traditional audio alarms, as a vibrating alarm can alert the user without disturbing others in the area.

Apply to Medical Care

Tactile feedback can be integrated into portable medical devices, replacing audible alarms with silent, unobtrusive tactile notifications. This allows users to perceive notifications even in noisy or distracting environments.

Apply to Bluetooth Gamepad / Game Controller

Game controllers have embraced haptic feedback, and "dual vibration" systems have become popular. It thanks to the tactile feedback provided by two vibration motors, one for light vibration and the other for heavy vibration feedback.

Get Haptic Feedback Motors in Bulk Step-by-step

FAQ

A haptic motor, also known as a haptic actuator, is a motor designed to provide tactile feedback to the user. It is commonly used in electronic devices such as smartphones, game controllers, and wearables to simulate the feeling of touch or force feedback.

Vibration and haptic motors are the common means used to provide feedback from a signal or touch. The feedback is vibration. Vibration is an effective indicator that an action has responded from a software or hardware.

Haptic motors can generate vibrations, pulses, or other tactile sensations to enhance the user experience and provide feedback in response to the user's interaction with the device. The technology is often used to create more immersive and interactive user interfaces, such as providing haptic feedback when typing on a virtual keyboard or interacting with a virtual reality environment.

Certainly! You can drive a vibration/haptic motor directly from a DC power source such as a battery. However, on the haptic side, where the goal is to respond to input and define vibration/amplitude profiles, dedicated vibration/haptic motor controller/driver circuits become critical.

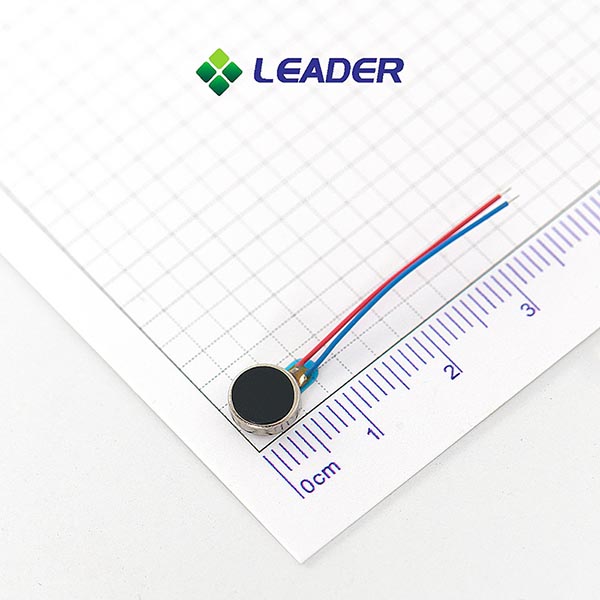

Wearable devices and many other consumer electronics products utilize vibro-tactile feedback to enhance user interaction. A popular piece of hardware that provides tactile feedback is the “pancake motor.”

The motor's vibrating mechanism and all moving parts are protected by a metal casing. To ensure durability, the motor wires are reinforced and adhesive-backed. When 3V voltage is supplied, the motor will produce obvious vibration.

Now take note that DRV2605L is a flexible low-voltage haptic vibration driver with haptic-effect library and smart-loop architecture.

The DRV2605 is a fancy motor driver. It designed to control haptic motors such as buzzers and vibration motors, rather than traditional stepper motors. Normally one would just turn those kinds of motors on and off, but this driver has the ability to have various effects when driving a vibe motor. These effects include raising and lowering vibration levels, creating a "click" effect, adjusting buzzer levels, and even synchronizing vibrations with music or audio input.

In this age of technology, we interact with electronic devices constantly. Haptic promises to be an important element of our future, transforming virtual worlds into not just visual but also tactile experiences. As technology advances, we expect a wider range of haptic motors to be available in the future.

At Leader Motor, we are committed to produce haptic motor with high quality. If you have any questions about our vibration motor, please feel free to contact us.

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your coreless motors need, on-time and on budget.