Manufacturer of 12 Volt Bldc Gear Motor - 2019 Good Quality Electric Hopper Motor/linear Vibration Motor/vibration Separator Motor – Leader Microelectronics

Manufacturer of 12 Volt Bldc Gear Motor - 2019 Good Quality Electric Hopper Motor/linear Vibration Motor/vibration Separator Motor – Leader Microelectronics Detail:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by providing worth added design and style, world-class producing, and repair capabilities for 2019 Good Quality Electric Hopper Motor/linear Vibration Motor/vibration Separator Motor, You may locate the cheapest price tag here. Also you may get premium quality goods and exceptional company here! Make sure you tend not to wait to speak to us!

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by providing worth added design and style, world-class producing, and repair capabilities for Hopper Motor, Linear Vibration Motor, Vibration Separator Motor, Our company is continuing to serve customers with high quality, competitive price and timely delivery. We sincerely welcome friends from all over the world to cooperate with us and enlarge our business. If you are interested in our products, please feel free to contact us. We would love to provide you with further information.

The linear motor has faster acceleration compared to the ERM vibration motor. It takes only 50ms from the standstill to the highest vibration level, while the ERM vibration motor needs 100ms~200ms. Higher accelerations result in better haptic feedback, so more and more mobile phone brands are starting to use linear motors instead of traditional motors.

Because of the mechanical structure, the ERM motor have brush abrasion during the working process. But, linear vibration motors are effectively brushless as they use a voice-coil to drive the mass. This means that the only moving parts that are prone to failure are the springs. These springs are modelled with FEA and are operated within their non-fatigue zone. So the lifetime of the linear motor is usually more than five times that of the traditional motor.

| Place of Origin | Guangdong, China (Mainland) | |

| Model Number | LD-X0612AF-0001F | |

| Usage | Mobile phone, Watch and Band,Massagers,Medical apparatus and instruments | |

| Certification | ISO9001,ISO14001,OHSAS18001 | |

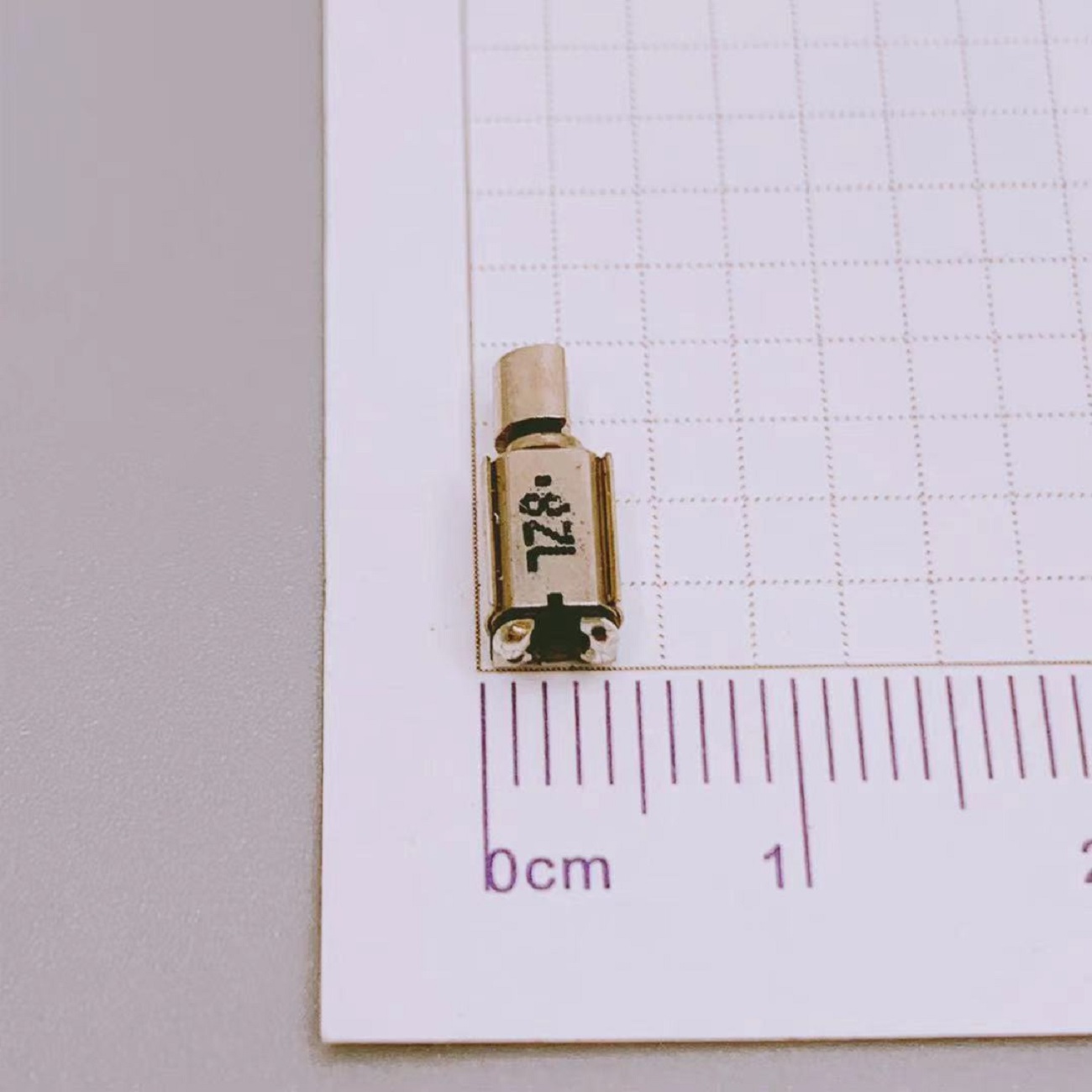

| Type | Micro Motor | |

| Feature | Vibration | |

| Rated current | 80mA Max | |

| Rated voltage | 2.0 Vrms AC | |

| Operating voltage | 0.1~2.1Vrms AC | |

| Operating frequency | 200±10Hz | |

| Size | 06mmx12mmx28mm | |

| Direction of vibration | X axis | |

| F0 Acceleration | Min 0.7Grms 100g 2.0Vrms 200HZ | |

| Life | 2.0Vrms, 2S ON,1S OFF, 150Hours | |

Main Export Markets of Our Mini Vibrating Motor:

South Asia: 43%

North America: 27%

Western Europe: 25%

Northern Europe: 5%

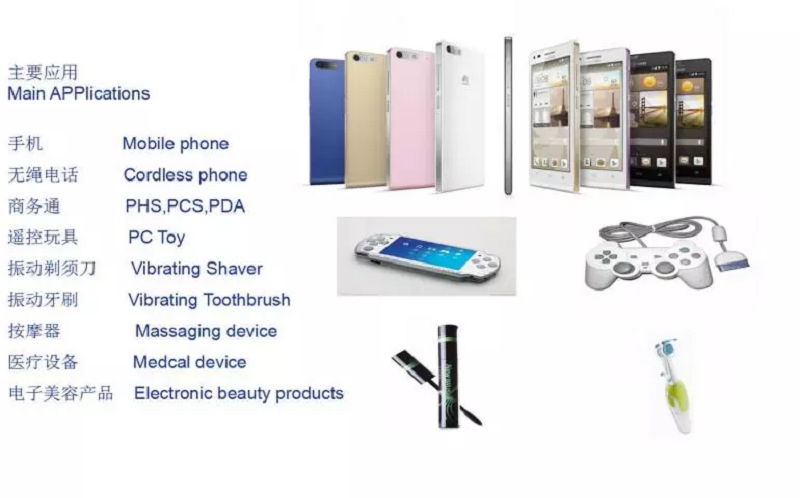

The application of Mini Vibrating Magnet motor :

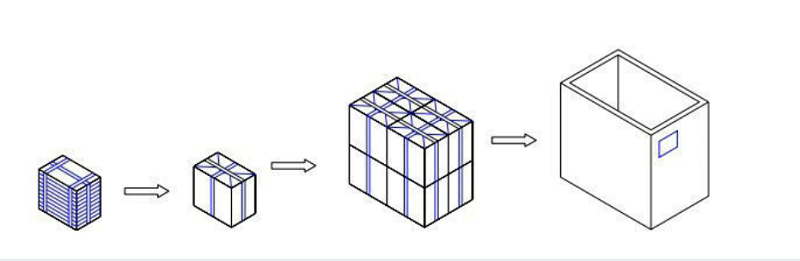

Packaging & Shippment:

1. 50 mini dc drive motors in each PS tray.

2. Every 20 capsules as a group, put a plastic cover on the group and wrap it in tape.

3. Put the wrapped group into a inbox.

4. Every 8 inboxes are put into an outer case by the ways standard as the drawing.

5. Quantity and batch number are written on the surface of the outer case.

Inspection Instrument:

Certificate:

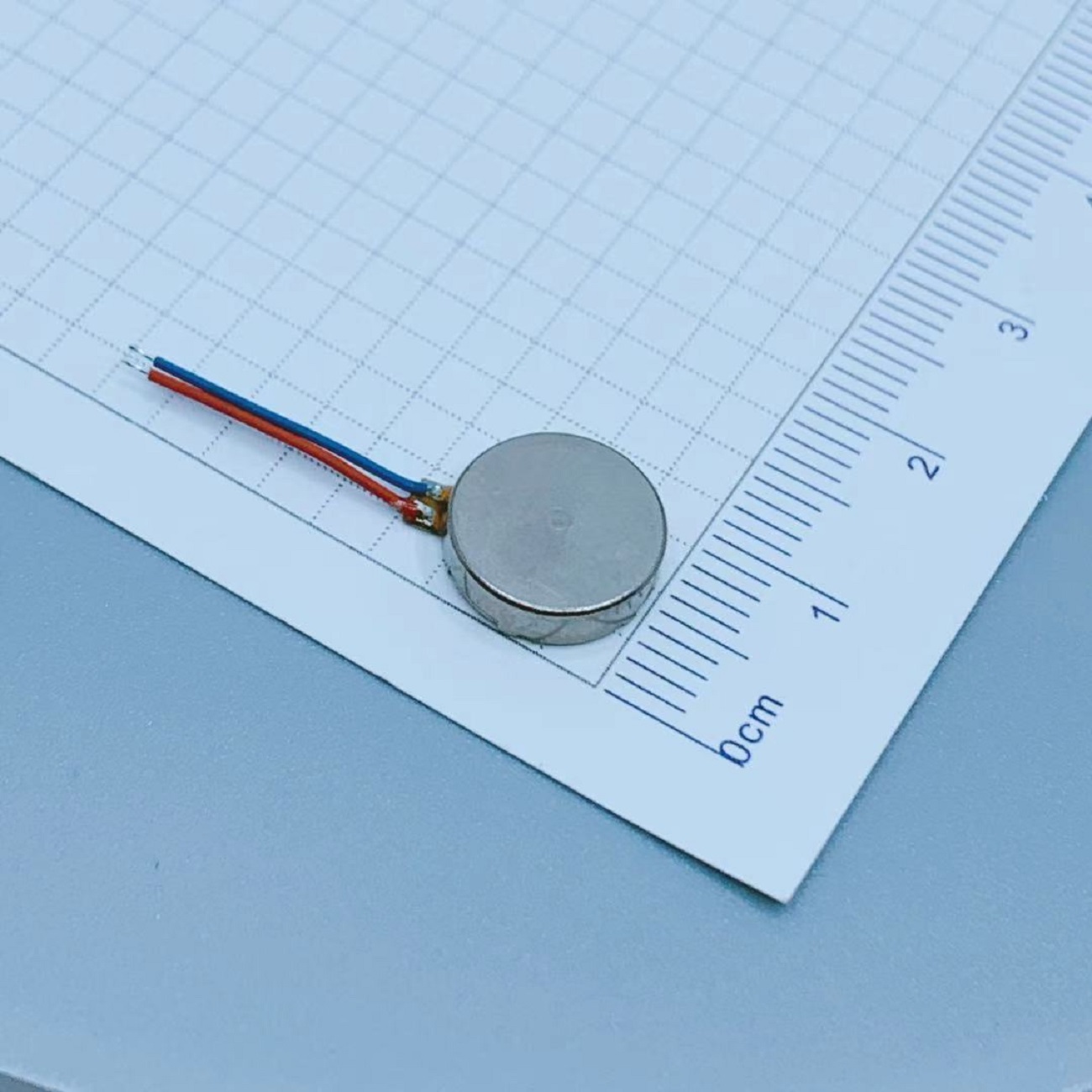

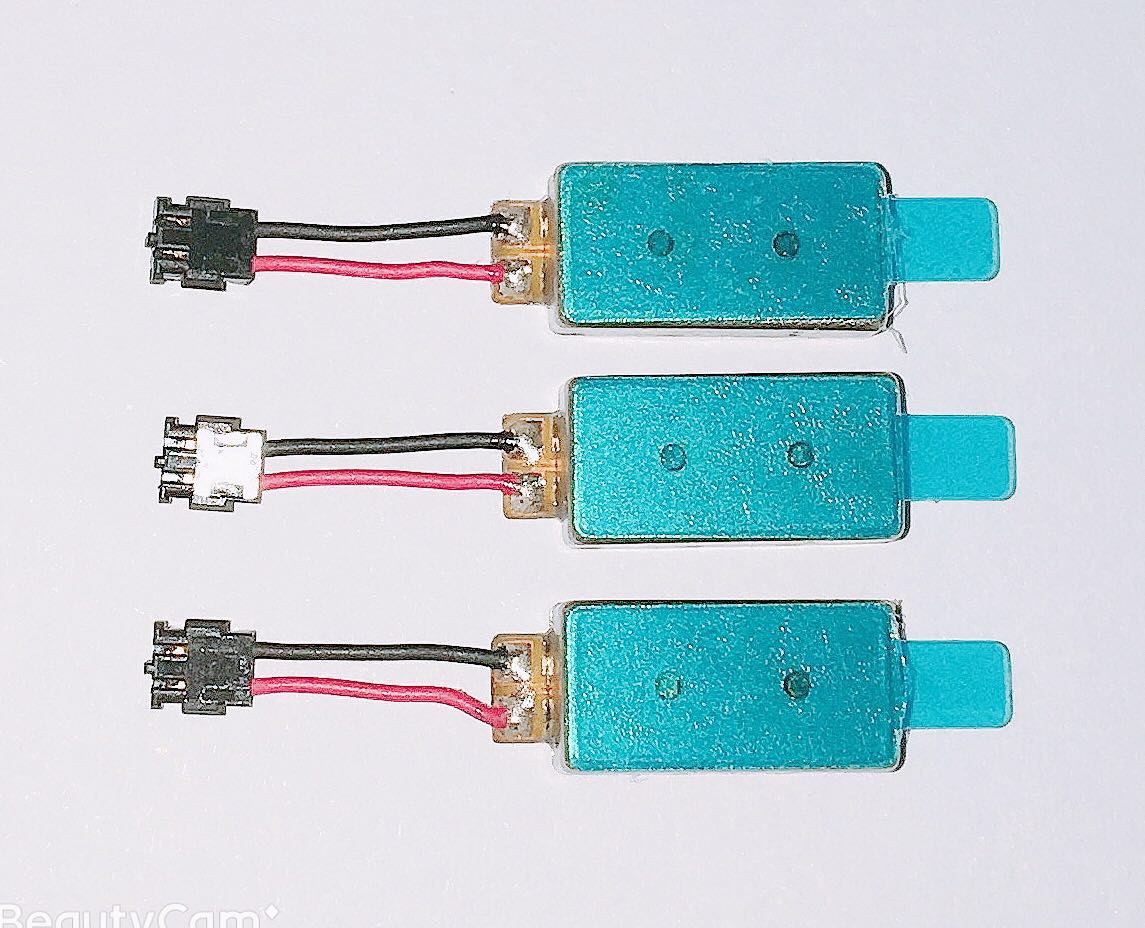

Product detail pictures:

Related Product Guide:

Understanding Gear Motors

DC Gear Motor and Its Uses in Industrial and Consumer Products

We provide fantastic energy in top quality and advancement,merchandising,gross sales and marketing and operation for Manufacturer of 12 Volt Bldc Gear Motor - 2019 Good Quality Electric Hopper Motor/linear Vibration Motor/vibration Separator Motor – Leader Microelectronics , The product will supply to all over the world, such as: Benin , Barcelona , Johor , Since always, we adhering to the open and fair, share to get, the pursuit of excellence, and creation of valuevalues, adhere to theintegrity and efficient, trade-oriented, best way , best valve business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

Quality Control

We have 200% inspection before shipment and the company enforces quality management methods, SPC, 8D report for defective products. Our company has a strict quality control procedure, which mainly tests four contents as follow:

01. Performance Testing; 02. Waveform Testing; 03. Noise Testing; 04. Appearance Testing.

Company Profile

Established in 2007, Leader Micro Electronics (Huizhou) Co., Ltd. is a high-tech enterprise integrating R&D, production, and sales of micro vibration motors. Leader mainly manufactures coin motors, linear motors, brushless motors and cylindrical motors, covering an area of more than 20,000 square meters. And the annual capacity of micro motors is nearly 80 million. Since its founding, Leader has sold nearly a billion of vibration motors all over the world, which are widely used on about 100 kinds of products in different fields. The main applications conclude smartphones, wearable devices, electronic cigarettes and so on.

Reliability Test

Leader Micro has professional laboratories with a full set of testing equipment. The main reliability testing machines are as below:

01. Life Test; 02. Temperature & Humidity Test; 03. Vibration Test; 04. Roll Drop Test;05. Salt Spray Test; 06. Simulation Transport Test.

Packaging & Shipping

We support air freight, sea freight and express.The main express are DHL, FedEx, UPS, EMS, TNT etc. For the packaging: 100pcs motors in a plastic tray >> 10 plastic trays in a vacuum bag >> 10 vacuum bags in a carton.

Besides, we can provide free samples on request.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.