CORED DC MOTOR

The most widely used motor type is the cored brushed DC motor, known for its cost-effective manufacturing and high-volume production. The motor consists of a rotor (rotating), a stator (stationary), a commutator (commonly brushed), and permanent magnets.

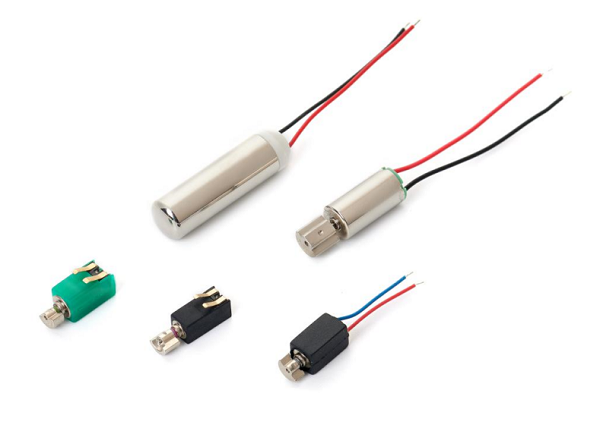

CORELESS DC MOTOR

Compared with traditional motors, coreless motors have a breakthrough in rotor structure. It uses coreless rotors, also known as hollow cup rotor. This new rotor design completely eliminates power losses caused by eddy currents formed in the iron core.

What are the advantages of coreless motors compared to standard DC motors?

1. No iron core, improve efficiency and reduce power loss caused by eddy current.

2. Reduced weight and size, suitable for compact and lightweight applications.

3. Compared with traditional cored motors, the operation is smoother and the vibration level is lower.

4. Improved response and acceleration characteristics, ideal for precision control applications.

5. Lower inertia, faster dynamic response, and rapid changes in speed and direction.

6. Reduce electromagnetic interference, suitable for sensitive electronic equipment.

7. The rotor structure is simplified, the service life is longer, and the maintenance requirements are reduced.

Disadvantage

Coreless DC motors are known for their ability to achieve extremely high speeds and their compact construction. However, these motors heat up quickly, especially when operated at full load for short periods of time. Therefore, it is recommended to use a cooling system for these motors to prevent overheating.

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your micro brushless motor need, on-time and on budget.

Post time: Aug-01-2024