Introduction

Two common types of DC motors are brushed motors and brushless motors (BLDC motors). As the name implies, brushed motors use brushes to commutate direction, allowing the motor to rotate. In contrast, Brushless motors replace the mechanical commutation function with electronic control. Both types work on the same principle, namely magnetic attraction and magnetic repulsion between the coil and the permanent magnet. Each has its own advantages and disadvantages, which may influence your choice based on the specific requirements of your application. Understanding the differences between brushed DC motors and brushless DC motors is critical to evaluating their performance. The decision to choose one type over another is based on a variety of criteria, including efficiency, life span and cost.

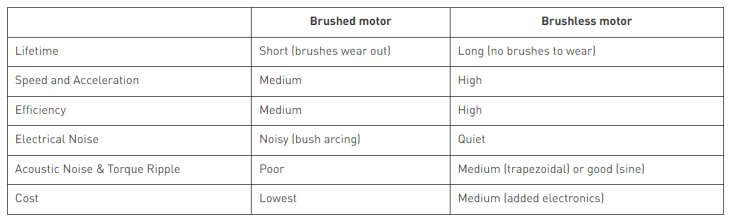

Important factors for the difference between brushed and brushless DC Motor:

#1. Better Efficiency

Brushless motors are more efficient than brushed motors. They convert electrical energy into mechanical energy with greater precision, thereby reducing energy waste. Unlike brushed DC motors, brushless motors do not experience the friction or energy losses associated with brushes and commutators. This improves performance, extends runtime, and reduces energy consumption.

Conversely, brushed motors are considered less efficient than brushless DC motors due to power losses associated with friction and energy transfer through the commutator system.

#2. Maintenance and Longevity

Brushless motors have fewer moving parts and lack mechanical connections, resulting in longer life and reduced maintenance requirements. The absence of brushes eliminates problems associated with brush wear and other maintenance issues. Therefore, brushless motors are often a more cost-effective option for users.

Additionally, brushed motors require more maintenance due to wear and tear on the brushes and commutator, which can lead to reduced performance and motor problems. To maintain optimal performance, brushes need to be replaced regularly.

#3. Noise and Vibration

In brushless motors, the winding current can be controlled, which helps reduce torque pulsations that can cause vibration and mechanical noise. Therefore, brushless motors generally produce less noise and vibration than brushed motors. because they have no brushes or commutators. The reduction in vibration and noise improves user comfort and minimizes wear and tear over extended use.

In a brushed DC motor, the brushes and commutator work together as a switching mechanism. When the motor is running, these switches are constantly opening and closing. This process allows high currents to flow through the inductive rotor windings, producing a little electrical noise due to the large current flow.

#4. Cost and Complexity

Brushless motors tend to be more expensive and complex due to the electronic control system for commutation. The higher price of brushless DC motors compared to brushed DC motors is mainly due to the advanced electronics involved in their design.

#5. Design and Operation

Brushless DC motors are not self-commutating. They require a drive circuit that uses transistors to control the current flowing through the motor winding coils. These motors use electronic controls and Hall effect sensors to manage the current in the windings, rather than relying on mechanical connections.

Brushed DC motors are self-commutated, which means they do not require a driver circuit to operate. Instead, they use mechanical brushes and commutators to control the current in the windings, thereby creating a magnetic field. This magnetic field creates torque, causing the motor to rotate.

#6. Applications

As the cost of vibration motors and their associated electronics continues to decrease, the demand for brushless motors and brushed motors is increasing. Brushless motors are very popular for smartwatches, medical devices, beauty devices, robots, etc.

But there are still places where brushed motors make more sense. There is a huge application of brushed motors in smartphones, e-cigarettes, video game controllers, eye massagers, etc.

Conclusion

Ultimately, the cost of brushed and brushless motors varies depending on the specific application and requirements. Although brushless motors tend to be more expensive, they offer superior efficiency and longer life. Brushed motors are great for daily applications, especially for people with limited electrical knowledge. In contrast, brushless motors are primarily used in situations where longevity is critical. However, brushed motors still occupy 95% of the motor market.

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your micro brushless motor need, on-time and on budget.

Post time: Oct-25-2024