The phone vibration motor is a kind of DC brush motor, which is used to realize the vibration function of the mobile phone.

When receiving a text message or telephone, the motor starts, driving the eccentric to rotate at a high speed, thereby generating vibration.

Today's mobile phone vibration motor are getting smaller and smaller to meet the needs of increasingly thin and light mobile phone bodies.

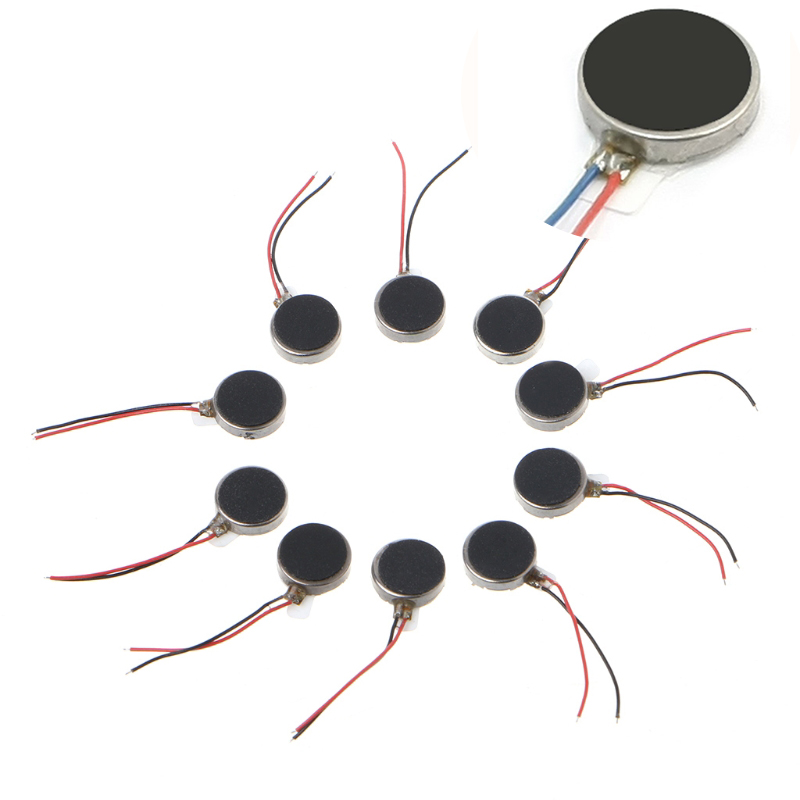

vibration motor cell phone

There are two basic types of vibration motor. An eccentric rotating mass vibration motor (ERM) uses a small unbalanced mass (we usually call it eccentric weight) on a DC motor, when it turns it creates a centrifugal force that translates to vibrations. A linear vibration motor(LRA) contains a moving mass attached to a wave spring, which creates a force when driven.

This type of vibration motor is commonly used in applications such as cell phones, game controllers, and wearable devices to provide users with tactile feedback. Some benefits of ERM vibration motors include:

-Simple and Compact Design: ERM vibration motors are typically small in size(φ3mm-φ12mm), making them easy to integrate into a variety of electronic devices.

-Cost-effective: They are relatively cheap to manufacture and offer good performance value. -Reliable Operation: ERM vibration motors are known for their durability and long-term reliable performance.

-Diverse installation and connection method, SMD Reflow, Spring Contact, FPC, Connectors, etc.

Coin Vibrator Motor - The Thinnest Motor In The World

Coin-type vibration motors, in particular, are popular in the mobile phone industry because of their slim designs. As the world's thinnest motor, the coin motor is only 2.0 mm thick, making it ideal for thin and light smartphones.

Linear resonant actuators (LRAs)

LRA motors offer faster response times and longer service life than eccentric rotating mass motors (ERMs). Because of these advantages, LRAs are commonly used in cell phones, wearables, and mobile phones to provide an enhanced vibration experience. The LRA is able to vibrate at a consistent frequency with minimal power consumption, providing superior haptic feedback for handheld devices. These vibrations are generated through electromagnetic forces and resonance, resulting in effective vertical vibrations.

iphone 6 vibration motor

Phone Vibration Motor Considerations

1. The motor has excellent comprehensive performance when working at its nominal rated voltage.

It is recommended that the operating voltage of the mobile phone circuit be designed as close as possible to the rated voltage.

2. The control module that supplies power to the motor should consider its output impedance as small as possible. The output voltage is greatly reduced when the load is prevented, which affects the vibration.

3. When the motor with mounting bracket is designed to position the card slot, the gap with the phone case should not be too large, otherwise additional vibration (mechanical noise) may occur. The use of rubber sleeves can effectively avoid mechanical noise, but it should be noted that the positioning groove on the casing and the rubber sleeve should be interference fit. Otherwise, the vibration output of the motor will be affected and the vibration feel will decrease.

4. Avoid being close to the strong magnetic area during transit or use. Otherwise, it is possible to make the magnetic steel of the motor magnet twist and affect the performance.

5. Pay attention to the welding temperature and welding time when welding. Excessive time and excessive temperature can damage the lead insulation.

6. Remove the motor unit from the package or avoid pulling the lead during the welding process. It is also not allowed to bend the lead at a large angle many times, otherwise the lead may be damaged.

small vibration motor

Mobile phone vibration motor scale

As more and more people own mobile phones, the number of companies that produce mobile phone motors has increased dramatically.

According to the market environment and development situation in recent years, the global market demand for mobile phone motors will continue to grow steadily.

From 2007 to 2023, the average annual growth rate of mobile phone motors has reached25%.

Established in 2007, Leader Microelectronics (Huizhou) Co., Ltd. is an international enterprise integrating R & D, production and sales. We mainly produce flat motor, linear motor, brushless motor, coreless motor, SMD motor, Air-modeling motor, deceleration motor and so on, as well as micro motor in multi-field application.

Welcome interested friends to consult, click here

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your micro brushless motor need, on-time and on budget.

Post time: Apr-05-2019