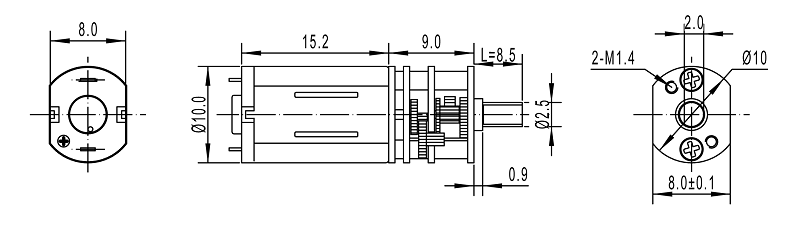

Diameter:10mm

Length:24.2mm

Characters:

1.Small size cylindrical dc gear motor with low speed and big torque

2. 10mm dc mini gear vibrating motor provide 0.01Nm torque and more reliable

3.Suitable to small diameter, low noise and big toque application

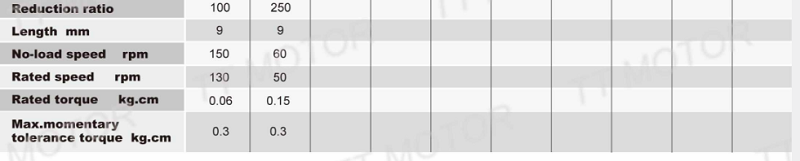

4.Reduction Ratio: 100、250

1. Application:

Electric lock, Intelligent robot, Medical endoscope,IP camera ,etc.

2. Mini dc gear vibrating motor dimensions (mm):

3. Coin mini dc gear vibrating motor technical data:

Every application has specific requirements of speed and torque. When a load demands high torque at low speed, use of a dc permanent magnet mini gearmotor capable of developing the torque would not be ideal and system efficiency would be low. A better solution in such cases is to introduce a miniature dc motor with gearing, adapting the motor to the load for speed, torque or inertia. The DC motor and gearbox assembly, or high torque DC gear motor, will provide greater efficiency in an economical solution.

A miniature gear motor using spur gears offer advantages in applications with a maximum current limit, where the lowest input friction and high efficiency are essential. The broad range of Portescap spur gearboxes is well adapted to our motor lines, spanning the range of motor diameters. A combination of our spur gearheads with our brush DC coreless motors provides a single, factory-integrated solution for demanding, high torque applications. Due to its spur compound geartrain arrangement, the micro dc gear motor provides the output along the same axis as the motor. The inherent design of our brush DC gear motors results in overall better efficiency and lower noise, benefiting a wide range of applications including medical pumps, security and access and watch winders. Alternately, the main advantages of Portescap planetary small dc gear motors are their high rated torque and high reduction ratio per gear train, utilizing high-quality composite materials. Portescap’s high-speed planetary brushless dc gear motors product line was designed for use on brushless motors with iron core windings. The gearboxes tolerate input speeds in the range of 10,000 to 70,000 rpm and output speeds of several thousand rpm. This facilitates a motor-gearbox unit of small dimensions that can provide extremely high values of speed and torque.

Post time: Sep-22-2018