In haptic feedback applications correctly mounting the 8mm mini dc motor is key to ensuring the user will receive the appropriate level haptic feedback. Micro shaker motors that are not designed to be PCB mounted, are typically mounted in a recessed pocket that is molded into the products housing. This is the preferred method of mounting as vibration energy is directly coupled to the products housing where it can be felt by the user.

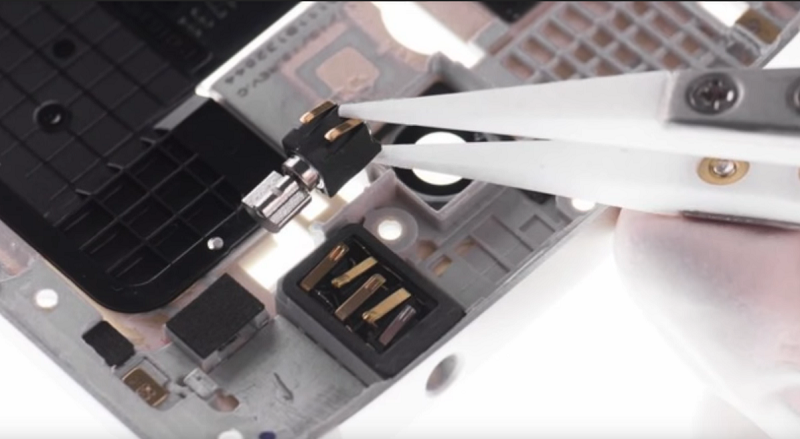

In touch screen haptic feedback applications, the vibration motor can be mounted directly to the frame of the display assembly.

While leaded components may be used, compression spring contacts are ideally suited for this application. Use of such smt vibrating motor will also eliminate time consuming secondary operations such as the hand soldering of lead wires, and soldering of through hole pins. They also can be easily replaced in the field should they fail.

A compression spring vibration motor may be mounted by molding a pocket into the shell of the devices housing. PCB contact pads mate with the contacts on the coin type motor. We can provide you with 3-D CAD files to aid you in the design process.

We do not have an official design guide. Information we have about our customers designs can not be disclosed due to confidentiality reasons. Fortunately, there is information available that is in the public domain. We have provided photos of actual products that exemplify how our vibration motors can be mounted.

Post time: Sep-19-2018