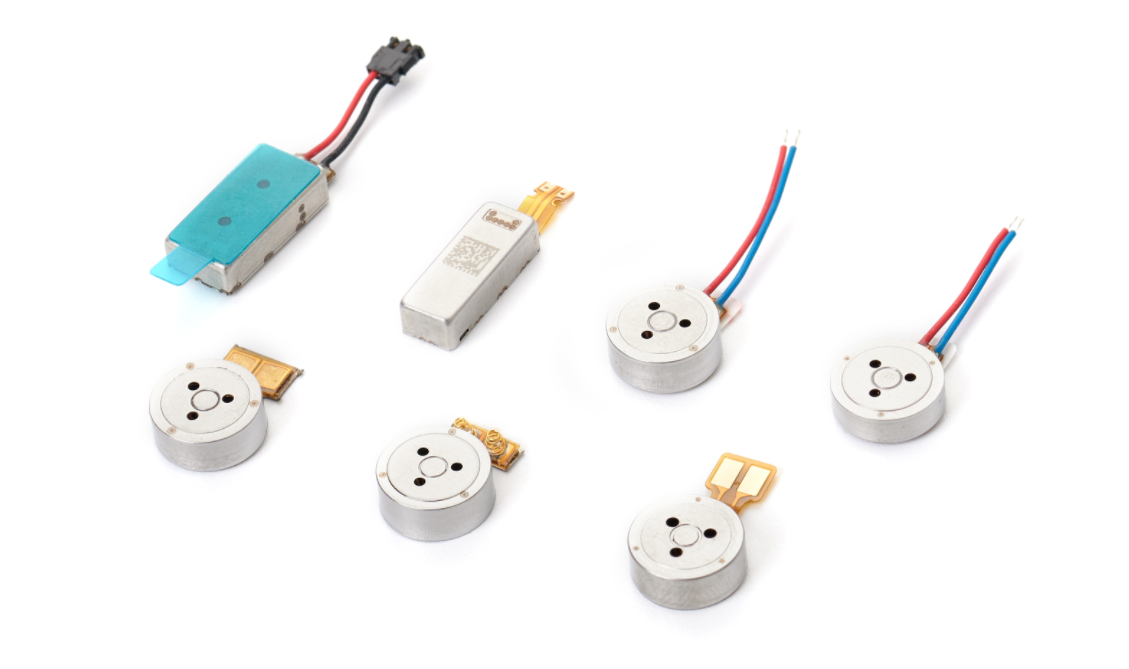

Linear vibration motors, also known as linear resonant actuators (LRA). Linear vibration motors, also known as linear resonant actuators (LRA), are compact, powerful, and efficient devices used in a wide variety of electronic devices and applications. These motors are designed to produce linear vibration, making them suitable for a variety of applications requiring precise and controlled vibration.

Working Principle

LRA vibration motor is a vibration motor that produces an oscillating force across a single axis. Unlike a DC eccentric rotating mass (ERM) motor, a linear resonant actuator relies on an AC voltage to drive a voice coil pressed against a moving mass connected to a spring.

Application Scenarios

Linear vibration motors can be used in a variety of devices, including mobile phones, wearables, game controllers, medical devices, and tactile feedback systems. They are used to provide haptic feedback, alarm notifications, and vibration-based user interfaces in these devices, thereby enhancing the user experience and improving the functionality of the device.

Key Features:

Linear vibration motors offer several advantages that make them suitable for various applications.

-Firstly, they are compact and lightweight, making them easy to integrate into portable devices.

-Additionally, they consume minimal power, thereby helping to prolong battery life in battery-operated devices.

-The precise control over frequency and amplitude allows for customization and optimization of haptic feedback.

-Furthermore, linear vibration motors produce vibrations with a limited range of motion, reducing the risk of damage to sensitive components.

Difference between LRA and ERM motors

Compared to ERM (eccentric rotating mass) motors, LRAs have distinct characteristics. LRAs generate vibrations in a linear direction, while ERMs create vibrations through the rotation of an eccentric mass. This fundamental difference affects the type of haptic feedback they provide. LRAs typically produce more nuanced and precise vibrations, allowing for finer control in applications such as touchscreens or virtual reality devices. On the other hand, ERMs generate stronger vibrations, making them suitable for applications that require a more pronounced tactile response, such as pagers or alarms.

However,LRA motors have longer life time with more than 1 million cycles.

In conclusion, linear vibration motors, or linear resonant actuators, provide controlled vibrations or haptic feedback in a linear direction. Their compact size, low power consumption, and customizable features make them highly sought-after for applications in consumer electronics, gaming, wearables, and haptic interfaces. If you are interested in this LRA motor, pls contact Leader motors supplier!

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your micro brushless motor need, on-time and on budget.

Post time: May-11-2024