Small Motor Manufacturers

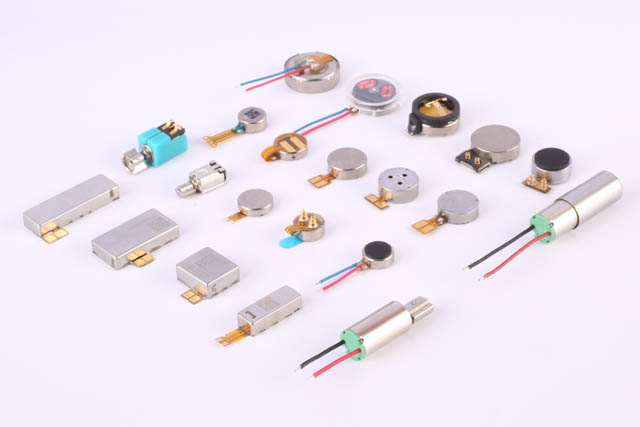

Leader is primarily focused on the production of small vibrating motors, which are essential components in various portable electronic devices. These motors are vital for creating haptic feedback. It allows users to feel and respond to alerts or notifications from their devices.

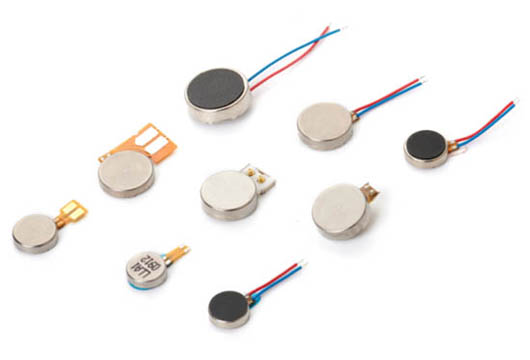

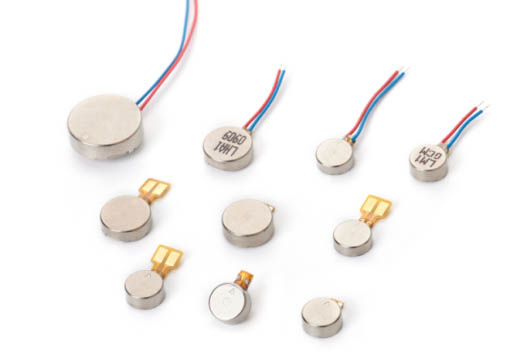

Leader specializes in designing and manufacturing high-quality coin-shaped tiny vibrating motor that are small, light-weight and consume minimal power. We offer a range of products that cater to different device applications, from basic pager motors to cutting-edge linear resonant actuators (LRA).

Leader's micro vibration motors are widely used in the wearable technology, medical equipment, automotive and gaming industries. The reliable haptic feedback is necessary for user engagement and satisfaction.

With a focus on innovative design, quality and customer satisfaction, Leader is a trusted supplier of tiny vibration motor for small vibrating device to electronics manufacturers around the world.

Small Vibrating Motor Types

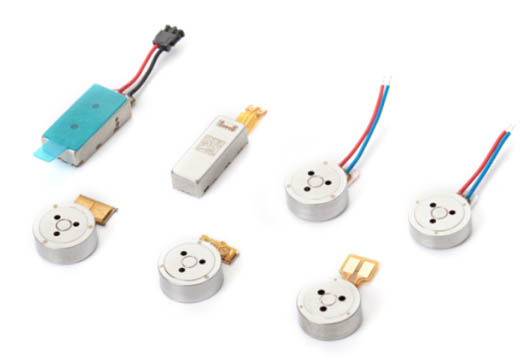

Leader produces four types of vibration motors: coin motors, linear motors, coreless motors and brushless motors. Each of these small vibration motor types has a unique set of advantages and applications, allowing Leader to provide a diverse range of solutions to meet the specific needs of our customers.

Still not finding what you're looking for? Contact our consultants for more available products.

Small Vibration Motor Technologies

Our team of engineers specializes in creating mini vibration motors and tactile feedback solutions utilizing four unique motor technologies. Each technology has its own characteristics, advantages and trade-offs. By understanding the unique advantages and compromises of each technology, we are able to design tailor-made solutions to meet the specific requirements of our customers' applications small vibrating device.

ERM motors are original technology for generating vibrations and offer several advantages. They are user-friendly, come in a wide range of sizes, and can be flexibly adjusted in vibration amplitude and frequency to suit any application.

These motors can be found in a variety of devices, from small smart watches to large truck steering wheels. At our company, we specialize in designing and manufacturing vibration motors with different motor technologies including iron core, coreless and brushless. These motors are available in cylindrical and coin-type forms.

One of the main advantages of ERM motors is their simplicity and ease of use.

DC motors, in particular, are easy to control, and if longevity is important, brushless vibration motors can be used.

However, there are some compromises to consider. There is a geometric relationship between vibration amplitude and frequency and speed, which means that it is not possible to adjust amplitude and frequency independently.

To meet different requirements, we offer three motor structures and technologies. Iron core motors offer a lower cost option, coreless motors offer a balance between cost and performance, and brushless motors offer the highest performance and longest life.

Linear resonant actuators (LRA) function more like a speaker than a traditional motor. Instead of cones, they consist of a mass that moves back and forth through a voice coil and spring.

A distinctive feature of the LRA is its resonant frequency, at which the amplitude reaches its maximum. Deviating even a few Hertz from this resonant frequency can result in significant losses in vibration amplitude and energy.

Due to slight manufacturing differences, the resonant frequency of each LRA will be slightly different. Therefore, a special driver IC is required to automatically adjust the drive signal and allow each LRA to resonate at its own resonant frequency.

LRAs are commonly found in smartphones, small touchpads, tracker pads, and other handheld devices weighing less than 200 grams. They come in two main shapes - coins and bars - as well as some square designs. The axis of vibration may vary depending on the form factor, but it always occurs along a single axis (unlike an ERM motor which vibrates on two axes).

Our product range is constantly evolving to meet specific customer needs. If you are considering using an LRA, it will be helpful to consult with one of our application design engineers.

How do they work?

Small brush vibration motors usually have a small conductive brush at the bottom. The brush is in contact with a rotating metal shaft that has a north and south pole. When an electric current is applied to the brush, it creates a magnetic field that interacts with the shaft, causing it to rotate. As the shaft rotates, it causes the brush to vibrate, causing the attached object to vibrate as well.

What are the benefits?

The main advantage of small vibration motors is their compact size, making them ideal for applications where space is limited. Additionally, they are cost-effective and easy to manufacture. These motors offer a variety of mounting options, including wire bonding with Molex or JST connectors.

What are the drawbacks?

One of the main limitations of small vibration motors is their relatively low power output compared to other types of vibration motors. Additionally, they are generally less efficient and require more electricity to produce the same level of vibrational force.

1. Compact size:

Small vibration motors are small and lightweight, making them ideal for integration into compact equipment and projects.

2. Vibration intensity:

Despite their compact size, these motors are capable of delivering significant vibration intensity, making them suitable for a wide range of applications.

3. Versatile applications:

These motors are often used in mobile devices, wearables, and various consumer electronics to provide tactile feedback and vibration alerts.

4. Applications:

Leader motor offers small vibration motors suitable for hobbyists, DIYers and professionals to incorporate into their projects.

How We Can Help

Although integrating a small vibrating motor into your application may seem simple, achieving reliable mass production may be more challenging than expected.

It is critical to consider a variety factors of small vibrating motors , including:

With our manufacturing and volume production, we can take care of this aspect so that you can focus on enhancing the value-added functionality of your application.

Example Small Vibration Motor Applications

Vibration motors of 7mm small coin vibration motor, 8mm diameter haptic motor, 10mm mini vibration motor to dia 12mm have a wide range of applications, and their main uses are as follows:

Vibration alerts are a useful way to provide notifications or warnings without relying solely on sound or visual cues. This is especially useful in situations where sounds are difficult to hear or visual cues may be ignored.

Vibration alarms are commonly used on a variety of devices, such as: Cell phone or pager: Many cell phones and pagers have vibrating motors that alert the user of incoming calls, messages, or notifications. This is particularly useful when the device is set to silent mode or the user is in a noisy environment.

Firefighter Radios: Firefighters often wear radios equipped with vibrating alarms. These alerts help them respond quickly to incoming calls or important messages, even in noisy or chaotic situations where audible alerts may be difficult to detect.

Medical Devices: Medical devices, such as respiratory assistance devices or pacemakers, may contain vibrating alarms to indicate specific operating or maintenance requirements. For example, a breathing assistance device may vibrate to alert the user that a filter needs to be changed, while a pacemaker may use vibration to indicate that the battery needs to be replaced.

Overall, vibration alerts provide an alternative way to grab the user's attention and provide important information or warnings in a variety of situations.

Having a range of vibrating motor small and haptic actuators optimized for screen haptic applications is important to delivering a high-quality user experience. Being able to simulate the feeling of pressing a physical button on a flat screen can greatly enhance the usability and intuitiveness of touch interfaces.

The use of haptic feedback in touch screens is becoming increasingly common across a variety of industries, including mobile devices, gaming consoles, automotive displays and industrial control panels.

It can improve user interaction by providing haptic feedback that confirms actions or helps users navigate menus and interfaces more efficiently.

The launch of heavy-duty tactile actuators designed for larger screens, such as point-of-sale systems, is also good news.

Larger screens typically require more powerful haptic actuators to provide sufficient vibration intensity and responsiveness. Equipping dedicated actuators for these applications ensures optimal performance and user satisfaction.

In summary, providing a variety of vibration motors and haptic actuators optimized for screen haptic applications can greatly enhance the user experience and make touch screens feel more tactile and intuitive.

Haptic feedback can also be a valuable addition to various non-screen user interfaces.

Capacitive touch surfaces, such as capacitive switch panels, can benefit from haptics, providing tactile confirmation when interacting with touch-sensitive controls. By embedding the vibration motor into the control column or handle, machine operators receive instinctive feedback that enhances their understanding and control of the equipment.

This type of haptic feedback goes beyond simple alert functionality and allows for more nuanced information to be conveyed to the user. By varying the vibration pattern, intensity or duration, a range of feedback can be provided to indicate different states, actions or warnings.

Additionally, haptic feedback can be applied to a variety of items, turning them into tactile user interfaces.

For example, integrating vibration motors into shoes could provide tactile feedback to guide the wearer, such as providing vibration direction to one foot at an intersection.

In vehicles, the steering wheel can use haptics as part of a lane departure warning system to provide vibrating feedback when the vehicle veers out of its lane.

The possibilities are vast, and integrating haptic feedback into user interfaces beyond the screen opens up new avenues for intuitive interaction and improved user experience.

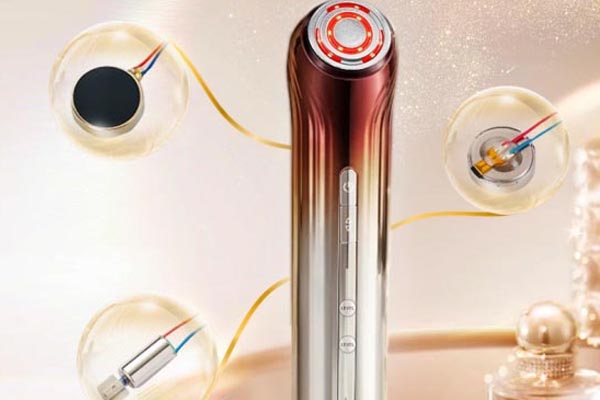

Vibration therapy is becoming increasingly popular in healthcare settings, with applications ranging beyond consumer products and adult toys.

Here are some examples:

Physical therapy: Vibration motors can be integrated into devices such as handheld massagers or vibrating massage balls to provide pain relief and relaxation. These devices are commonly used by physical therapists to soothe sore muscles, increase blood circulation, and relieve muscle tension.

Pain Management: Vibration devices can help treat chronic pain, such as arthritis or fibromyalgia. By applying controlled vibrations to specific areas of the body, these devices can help reduce the sensation of pain, provide temporary pain relief, and improve overall comfort.

Massage Therapy: Massage therapists typically use vibrating handheld or stationary massage tools to provide deep tissue massage and target specific trigger points. This helps relieve muscle knots, increases blood flow, and promotes overall relaxation.

In all of these healthcare applications, precise control of micro vibration motor frequency and amplitude is critical to ensure optimal results.

LEADER Micro Motor offers customization options that help tailor vibration characteristics to the specific needs and requirements of each application.

Our capabilities

We can support you through the whole journey from prototype to high volume cost-effective mass production:

We specialize in designing small vibration motors and mechanisms for a variety of applications, including massage, medical, consumer products and other small vibration device. Our experienced team specializes in creating innovative, efficient designs to meet your specific needs.

Our production lines are highly flexible, allowing us to support high-volume production and high value-added builds. Whether you require a large quantity of micro vibrator or a custom variant, we have the capabilities to meet your requirements.

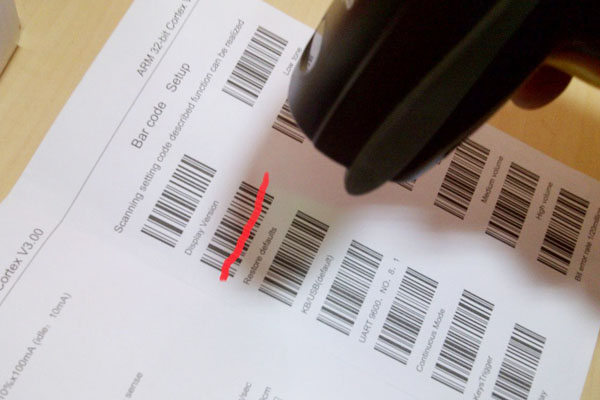

To ensure the highest quality and performance, we use in-house designed dynamometers to test and validate every sample and production batch. Our rigorous testing process ensures our mobile vibration motor meet the highest reliability and efficiency standards.

We are committed to delivering industry-leading product consistency. Our quality control measures ensure that each motor meets your exact specifications and performance expectations. Additionally, our dedicated after-sales support team is on hand to assist you throughout the product lifecycle.

With our streamlined production processes of mobile vibration motor and efficient project management, we are committed to delivering your parts on time and to your precise requirements.

As an ISO 9001:2015 certified company, we adhere to internationally recognized quality management standards. This certification demonstrates our commitment to providing superior products and services, including micro vibrating motor and DC motors.

Why Buy Small Vibrating Motors From LEADER-Motor?

Our small vibration motors are manufactured in our own factory, ensuring consistent quality and reliability of mini vibrating motor. We have implemented strict quality control measures to meet the highest industry standards.

As a direct manufacturer, we eliminate the need for middlemen or agents, allowing us to offer competitive prices without compromising on quality of miniature vibration motor.

As a professtional 8mm coin vibration motor manufacturer, we have established partnerships with reputable express companies such as DHL, FedEx, UPS, etc., allowing us to provide fast and reliable delivery services worldwide. Whether you need air or sea freight, we can meet your needs.

We have a hassle-free online request and quote system. Simply submit your request and our team of professionals will respond immediately with a detailed quote and specifications of mini vibration motors tailored to your needs.

Our team consists of 17 experienced vibration motor small technical experts who are ready to provide technical support throughout the product selection and implementation process.

Choose LEADER-Motor for your small vibration motor needs and experience the benefits of factory quality, fast delivery and excellent customer support. Submit your request of micro vibration motors today to get started!

Consult Your Leader Experts

We help you avoid the pitfalls to deliver the quality and value your micro motor need, on-time and on budget.

Micro Vibration Motor FAQ

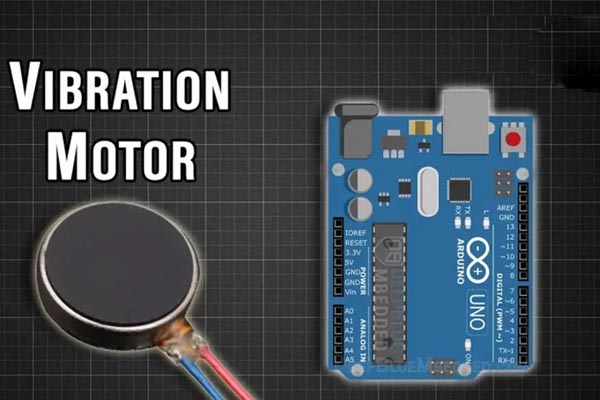

To connect a micro vibration motor, you will typically need to identify the positive and negative terminals of the tiny vibrating motor. Then, connect the positive terminal to a power source with a suitable voltage and current rating. Finally, connect the negative terminal to a ground or return path. Depending on your specific application, you may also need to add additional circuitry such as a transistor or driver, to control the small vibration motors.

Micro vibration motors are typically measured based on various performance parameters such as operating voltage, current consumption, speed and efficiency. These 8mm micro coin vibration motor parameters can be measured using a variety of testing equipment including multimeters, oscilloscopes, dynamometers and power analyzers. Additionally, vibration motors can be evaluated based on physical characteristics such as size, weight and durability. Overall, the measurement techniques used for micro vibration motors can vary depending on the specific application and performance requirements.

Micro vibration motors are used to create haptic feedback. It is the tactile or touch sensation that occurs when you interact with an electronic device. By providing feedback through vibrations in response to user input or device notifications, these mini vibrating motors help to make the user experience more engaging and intuitive. The primary application of vibration motors is in the consumer electronics industry, where they are used in devices such as cell phones, smartwatches and gaming controllers.