Supply OEM/ODM Gold Sand Stone Quaarry Sand Mini Linear Vibrating Screen

We have a professional, efficiency team to provide quality service for our customer. We always follow the tenet of customer-oriented, details-focused for Supply OEM/ODM Gold Sand Stone Quaarry Sand Mini Linear Vibrating Screen, We sincerely welcome overseas buyers to refer to for your long-term cooperation and also the mutual development.We strongly think that we can do better and far better.

We have a professional, efficiency team to provide quality service for our customer. We always follow the tenet of customer-oriented, details-focused for Gold Sand Vibrating Screen, Quarry Sand Vibrating Screen, Stone Vibrating Screen, We’ve our own registered brand and our company is developing rapidly owing to high quality merchandise, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence.

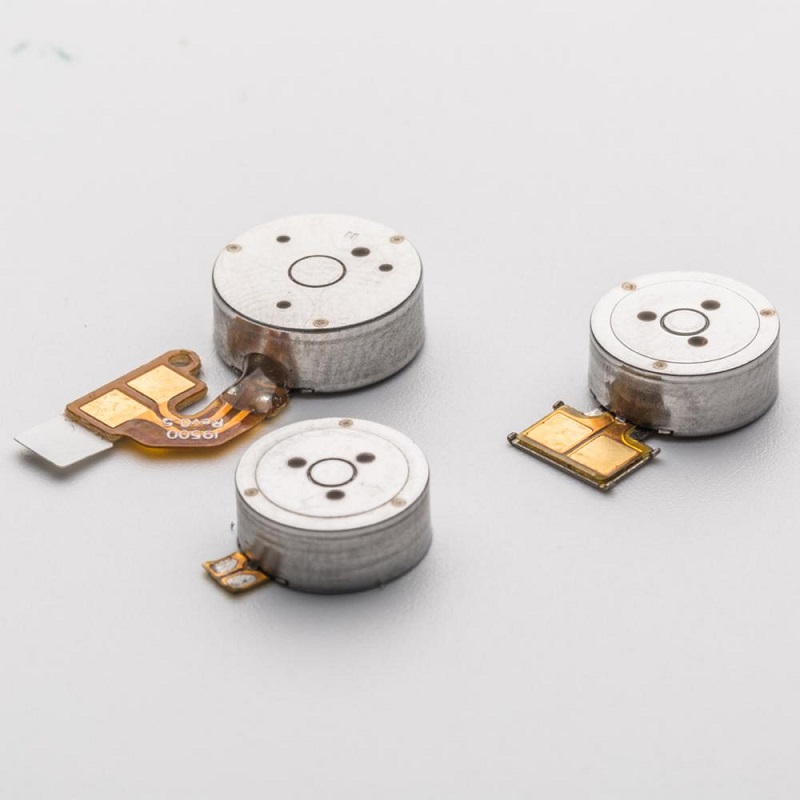

The linear vibration motor mobile has faster acceleration compared to the ERM vibration motor. It takes only 50ms from the standstill to the highest vibration level, while the ERM vibration motor needs 100ms~200ms. Higher accelerations result in better haptic feedback, so more and more mobile phone brands are starting to use linear motors instead of traditional motors.

Because of the mechanical structure, the ERM motor have brush abrasion during the working process. But, linear vibration motors are effectively brushless as they use a voice-coil to drive the mass. This means that the only moving parts that are prone to failure are the springs. These springs are modelled with FEA and are operated within their non-fatigue zone. So the lifetime of the linear motor is usually more than five times that of the traditional motor.

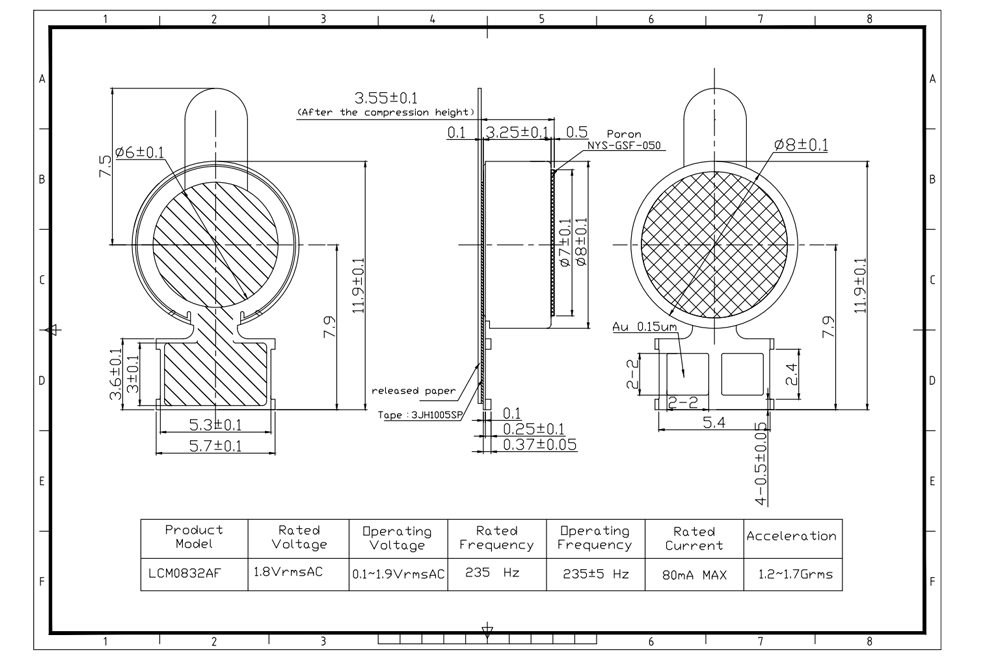

Product Technical Parameters of Linear Vibrating motor :

| Place of Origin | Guangdong, China (Mainland) | |

| Model Number | LCM0832AF | |

| Usage | Mobile phone, Watch and Band,Massagers,Medical apparatus and instruments | |

| Diameter | 8mm | |

| Thickness | 3.2mm | |

| Certification | ISO9001,ISO14001,OHSAS18001 | |

| Type | Micro Motor | |

| Feature | Vibration | |

| Rated frequency | 235Hz | |

| Operating frequency | 235±5 Hz | |

| Rated current | 80mA Max | |

| Rated voltage | 1.8(Vms )AC | |

| Operating voltage | 0.1~1.9(Vms)AC | |

| F0 Acceleration | 1.2~1.7G | |

| Life | 1.8V, 2S ON,1S OFF, 1,000,000 cycles | |

The main features of Mini Linear level motor :

(1) This is the newly developed Linear Motor vibrating in direction Z with a very long life time of 1 million cycles at the test mode 2s On 1s Off as one cycle.

(2) This Linear Motor also have a very strong acceleration/ vibration force at its peak acceleration value around 1.8G, much stronger than other normal brush type coin motors at 0.6-0.8G usually.

(3) To use this Linear Motor, users need to add IC drivers in the PCB to activate this motor.

(4) This Linear Motor is specially for high-end and high reliable electronic consumer products.

Main Export Markets of Our Mini Vibrating Motor:

South Asia: 43%

North America: 27%

Western Europe: 25%

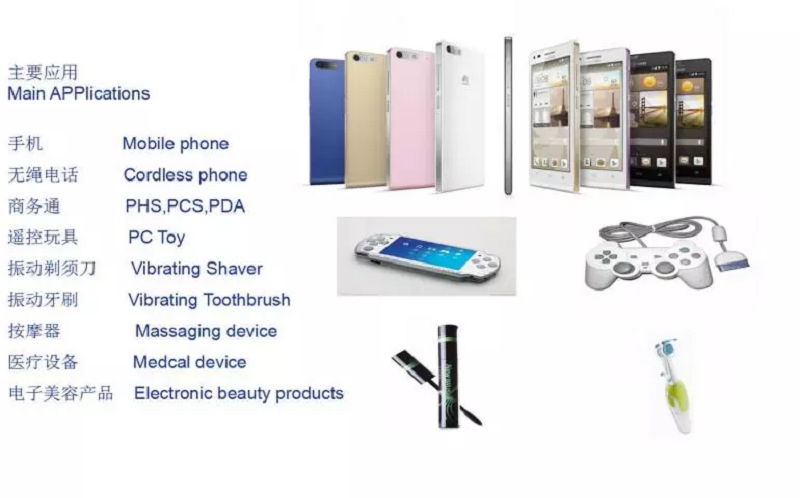

The application of Mini Vibrating Magnet motor :

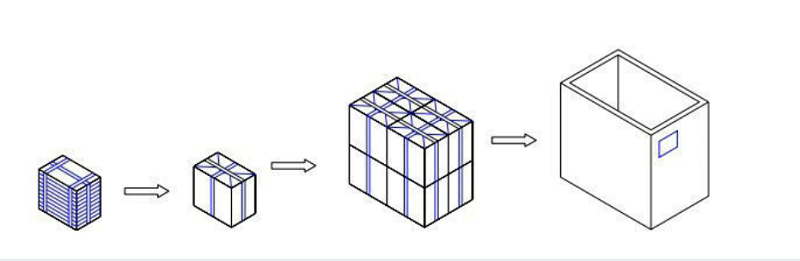

Packaging & Shippment:

1. 50 mini dc drive motors in each PS tray.

2. Every 20 capsules as a group, put a plastic cover on the group and wrap it in tape.

3. Put the wrapped group into a inbox.

4. Every 8 inboxes are put into an outer case by the ways standard as the drawing.

5. Quantity and batch number are written on the surface of the outer case.

Inspection Instrument:

Certificate:

Quality Control

We have 200% inspection before shipment and the company enforces quality management methods, SPC, 8D report for defective products. Our company has a strict quality control procedure, which mainly tests four contents as follow:

01. Performance Testing; 02. Waveform Testing; 03. Noise Testing; 04. Appearance Testing.

Company Profile

Established in 2007, Leader Micro Electronics (Huizhou) Co., Ltd. is a high-tech enterprise integrating R&D, production, and sales of micro vibration motors. Leader mainly manufactures coin motors, linear motors, brushless motors and cylindrical motors, covering an area of more than 20,000 square meters. And the annual capacity of micro motors is nearly 80 million. Since its founding, Leader has sold nearly a billion of vibration motors all over the world, which are widely used on about 100 kinds of products in different fields. The main applications conclude smartphones, wearable devices, electronic cigarettes and so on.

Reliability Test

Leader Micro has professional laboratories with a full set of testing equipment. The main reliability testing machines are as below:

01. Life Test; 02. Temperature & Humidity Test; 03. Vibration Test; 04. Roll Drop Test;05. Salt Spray Test; 06. Simulation Transport Test.

Packaging & Shipping

We support air freight, sea freight and express.The main express are DHL, FedEx, UPS, EMS, TNT etc. For the packaging: 100pcs motors in a plastic tray >> 10 plastic trays in a vacuum bag >> 10 vacuum bags in a carton.

Besides, we can provide free samples on request.