Leader - The Surface Mount (SMD/SMT) Vibration Motors Specialists!

Leader is a leading Chinese factory specializing in Surface Mount (SMD/SMT) Vibration Motors, catering to electronic products, medical devices, and robotics industries. Our innovative designs ensure optimal performance, enhancing productivity in compact spaces.Looking for ultra-compact motors? Discover how our smallest BLDC motors offer powerful performance in a tiny form factor!

As a trusted OEM supplier, Leader has garnered years of experience in providing precision-engineered vibration motors with ISO and CE certifications. Our products are exported to over 30 countries worldwide, reflecting our commitment to quality and reliability.

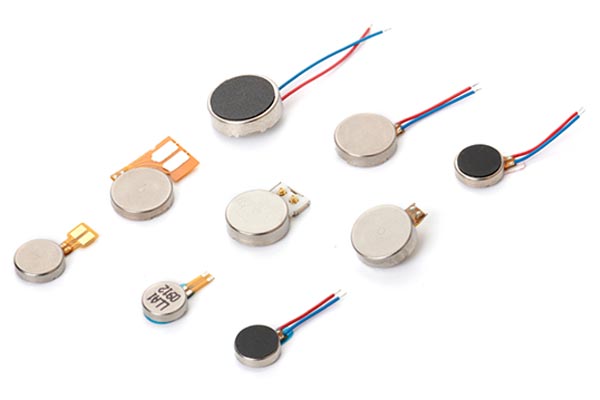

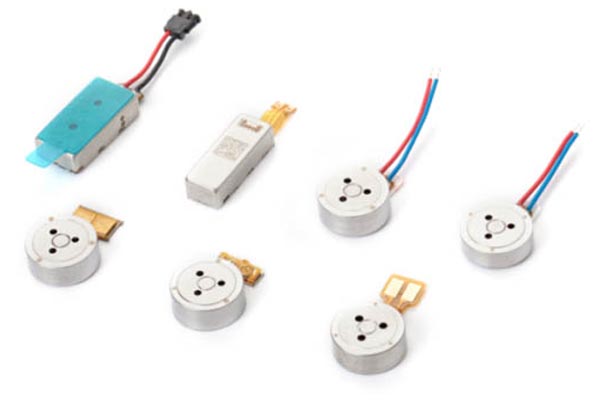

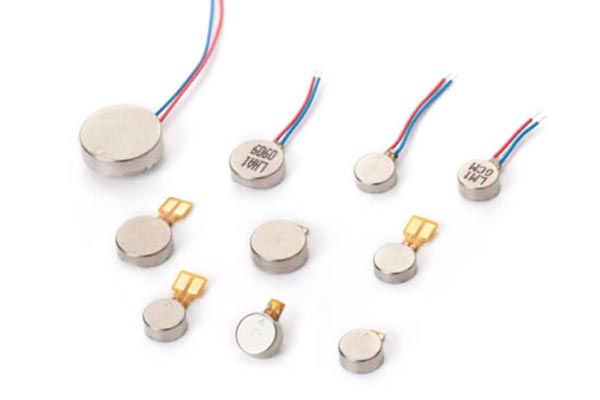

Leader offers a diverse range of Surface Mount (SMD/SMT) Vibration Motors, providing ample options for various working conditions. Trust Leader for exceptional vibration motor solutions tailored to your specific needs.

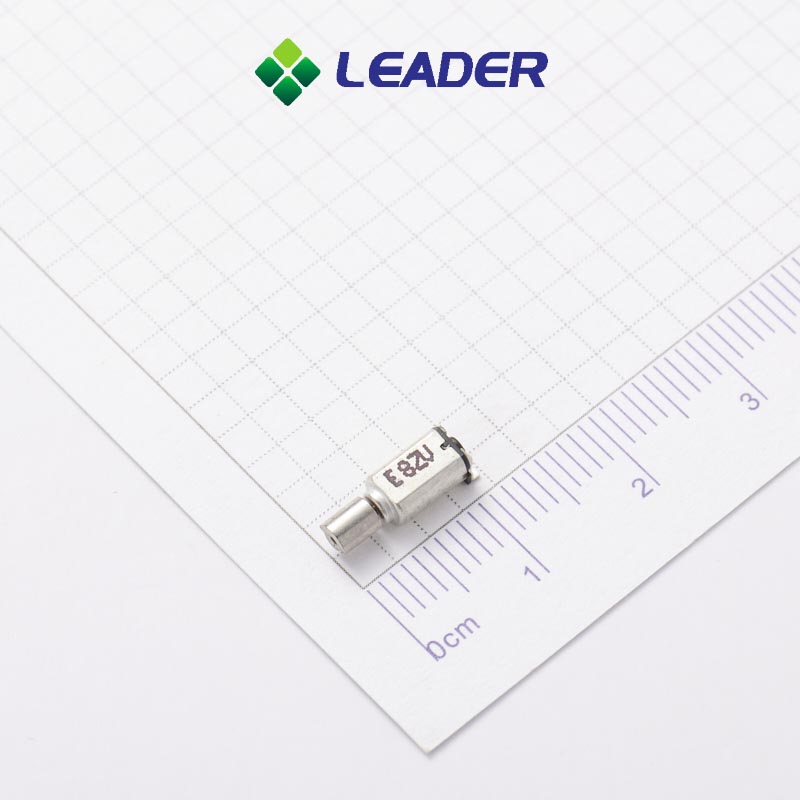

SMT Type Vibration Motor

SMT Vibration Motor Datasheet

| Models | Size(mm) | Rated Voltage(V) | Rated Current (mA) | Rated(RPM) | Voltage(V) |

| LD-GS-3200 | 3.4*4.4*4 | 3.0V DC | 85mA Max | 12000±2500 | 2.3-3.6V DC |

| LD-GS-3205 | 3.4*4.4*2.8mm | 2.7V DC | 75mA Max | 14000±3000 | 2.3-3.2V DC |

| LD-GS-3215 | 3*4*3.3mm | 2.7V DC | 90mA Max | 15000±3000 | 2.3-3.2V DC |

| LD-SM-430 | 3.6*4.6*2.8mm | 2.7V DC | 95mA Max | 14000±2500 | 2.3-3.2V DC |

Advantages of SMT Motor

Thanks to advanced surface mount technology, the size of the miniature SMT motors is greatly reduced, making them easy to carry and move around. It is also more suitable for application scenarios that require a compact solution.

SMT motors have high energy conversion efficiency and power density, which can provide stable power output.

The structure of the miniature SMT motor has been precisely designed and manufactured to have high reliability, which can ensure stable operation for a long time.

The SMT motor has a fast response time and is able to start and stop quickly, adapting to the needs of different applications.

The miniature SMT motor has a long life. It can withstand multiple start and stop cycles and has a long service life.

SMT motors are simple in construction and easy to disassemble and repair, reducing maintenance costs and time.

SMT motors are suitable for a wide variety of applications. They can be customized and adapted as needed.

Materials And Processes

The core part of SMT motors is magnetic materials, usually using materials with high permeability, low coercivity and high magnetic energy. For example, ferrite, chintie boron and so on. These materials can provide a strong magnetic field and high energy conversion efficiency.

Winding technology for SMT motors is also one of the keys. High-precision and high-efficiency winding equipments are usually used to ensure the precise number of turns, wire diameters and alignment of the coils to improve the performance of the motor.

Components of SMT motors often require precision machining and assembly to ensure accuracy and reliability. For example, components such as rotors, stators and bearings need to be precision machined and selected to ensure that they fit well with the rest of the motor.

SMT motors utilize surface mount technology. Mounting electronic components and circuits directly on the circuit board reduces size and weight. This improves the compactness and reliability of the motor.

Soldering is a critical part of the manufacturing process. SMT motors are usually soldered using advanced soldering processes such as laser soldering, ultrasonic soldering, etc. This ensures reliable and consistent of the soldering quality.

The SMT motor manufacturing process requires multiple inspection and testing to ensure quality and reliability at every step.

Application of SMT Motor

1.Electronics: SMT motors can be used in a variety of electronic products, such as cell phones, computers, TVs, etc., to provide efficient power management functions.

2.Medical equipment: Micro SMT motors can be used in medical equipment, such as ventilators, syringe pumps, etc., to provide stable and reliable power output.

3.Robotics: Micro SMT motors can be used in various types of robots, providing compact and efficient power solutions.

Working with Us

It is important to provide the following information: dimensions, application, desired speed and voltage. Additionally, providing application prototype drawings (if available) helps ensure accurate customization of the micro vibrating motor and we can provide vibration motor datasheet asap.

Our main products are coin vibration motor, linear vibration motor, brushless vibration motor, SMT vibration motor and coreless motor.

Yes, we offer free sample of the electrical vibration motor. Please contact us for more details on how to proceed.

You can choose multiple payment methods, such as T/T (bank transfer) or PayPal. If you wish to use an alternative payment method, please contact us in advance to discuss available options.

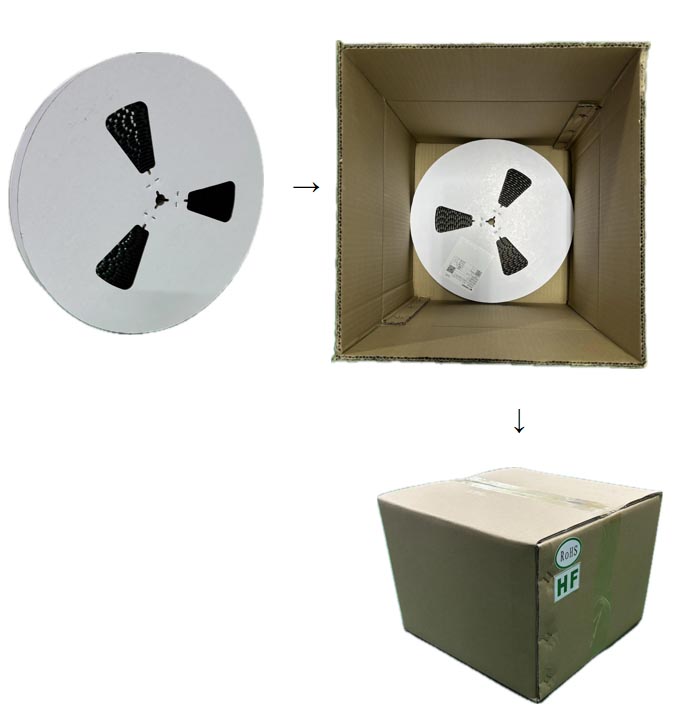

Air shipping / DHL / FedEx / UPS with 3-5 days. Sea shipping with about 25 days.