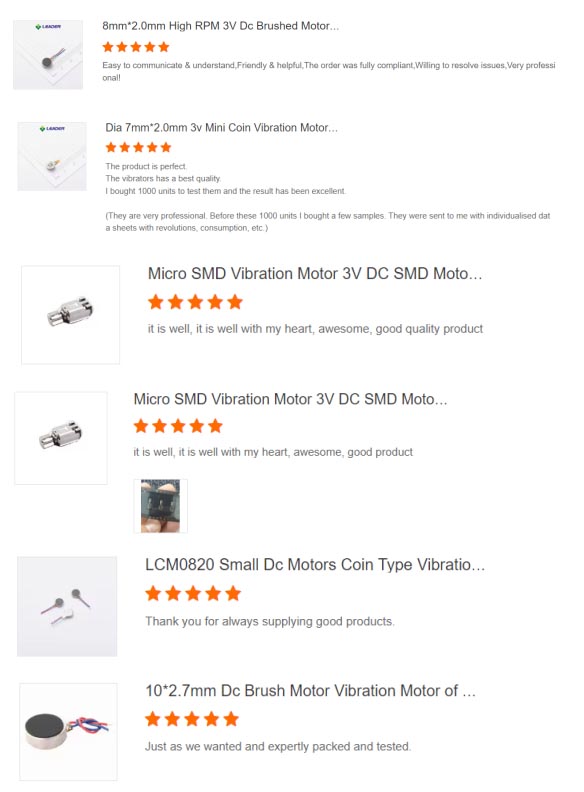

High-Quality Coin Vibration Motors from a Leading Manufacturer

Welcome to LEADER, your trusted manufacturer and supplier of high-quality Coin Vibration Motors. Our Flat Vibration Motors are designed to meet the demanding needs of various industries, providing consistent performance and reliability.

LEADER Motor specializes in coin vibration motors, also known as shaftless or pancake vibration motors. The coin motor is unique in that its eccentric mass is located within a compact circular body, hence the name "pancake" motor. Due to their small size and thin profile (often only a few millimeters), these motors have limited amplitude, making them ideal for applications where space is limited.

It is worth noting that the starting voltage of the coin vibration motor is relatively high compared to the cylinder pager vibration motor. Typically, a coin motor requires about 2.3 volts to start (nominal voltage is 3 volts). If this is not considered in the design, it may result in the coin type vibration motor not starting when the application is in a certain orientation. This challenge arises because, in the vertical direction, the coin motor needs to exert enough force to move the eccentric mass to the top of the shaft during the initial cycle. To maximize the performance and reliability of a coin motor, it is critical to consider its specific characteristics and design requirements. By understanding these factors, designers can effectively incorporate coin vibration motors into their applications to achieve optimal results.

Why choose LEADER Coin Vibration Motor?

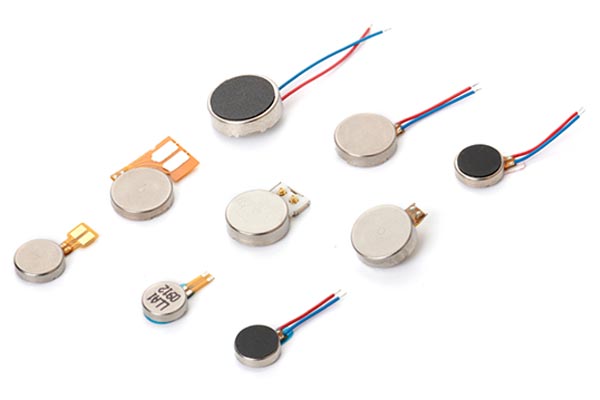

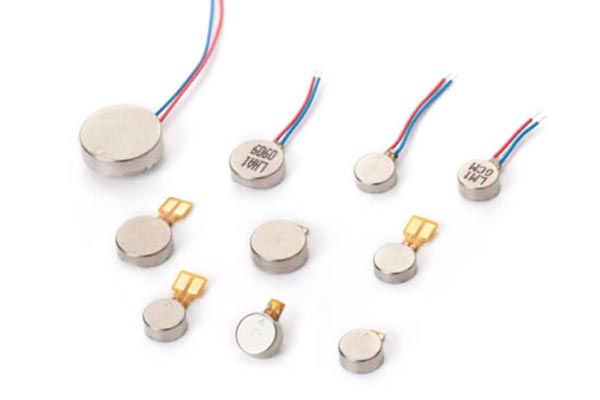

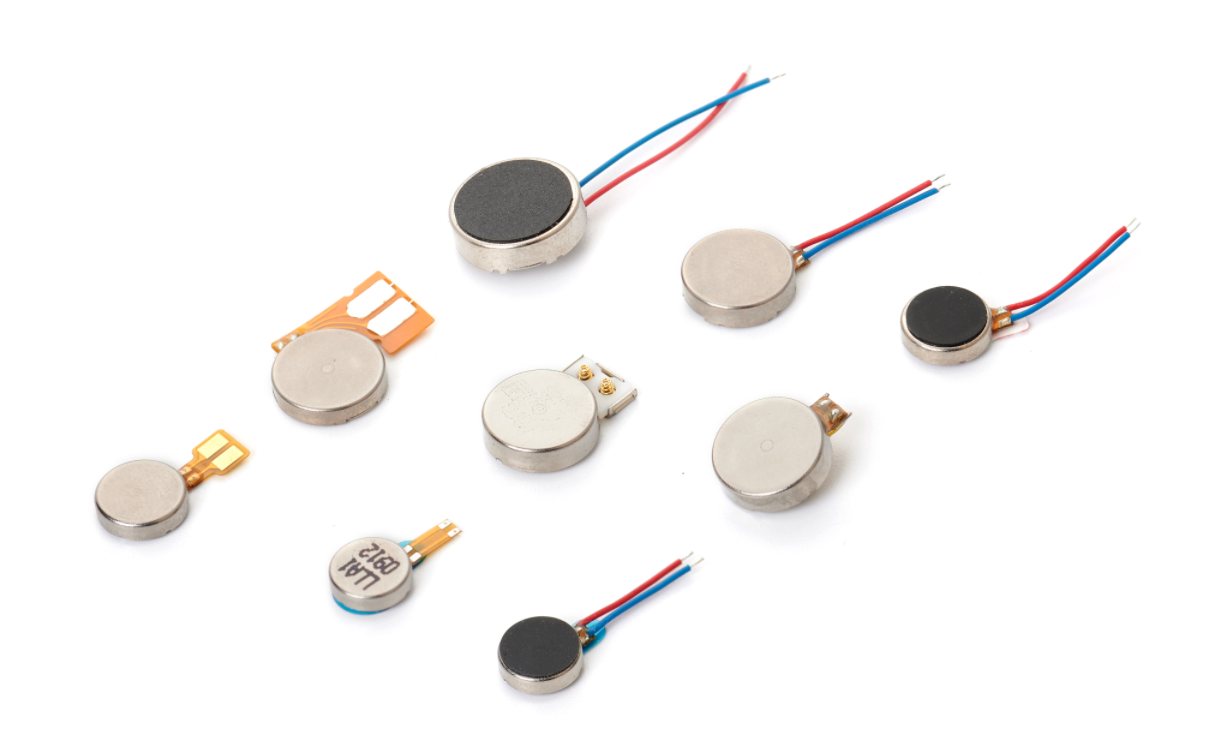

Leader Micro is a leading supplier of coin vibration motors, also called pancake or flat vibrator motors, generally in Ø7mm small coin vibration motor, 8mm diameter pancake vibration motor , Ø10mm and Ø12mm diameters.

Our pancake motors are highly compact and easily integrated into numerous designs, as they have no external moving parts and can be secured in place using a strong permanent self-adhesive mounting system.

We can supply our coin vibrator with various connectors, spring contacts, FPC, or bare contact pads.

We can provide customized designs and variations of coin motor according to the base design, such as modifications to the lead length and connectors.

Coin Type Vibration Motor

At LEADER, we offer a range of options for coin motors including different connectors, spring contacts, flexible printed circuit (FPC) boards or exposed contact pads. If the quantity is reasonable, we can even design a custom FPC board for your specific application.

Our vibration motors operate by using a rotating eccentric weight to create horizontal vibrations. By throwing the body off balance through this eccentric rotation, the motor produces the desired vibration. This rotating motor effectively converts received signals into vibrations in mobile devices. The best part is that operation of small vibration motor can be achieved with a simple DC power on/off, eliminating the need for a separate driver IC.

Key features of our coin vibration motors include high vibration force, smooth rotation and easy integration into smartphones, tablets, wearables, toys and game consoles.

Ready for advanced micro solutions? Discover how our micro brushless motors deliver high performance with exceptional durability!

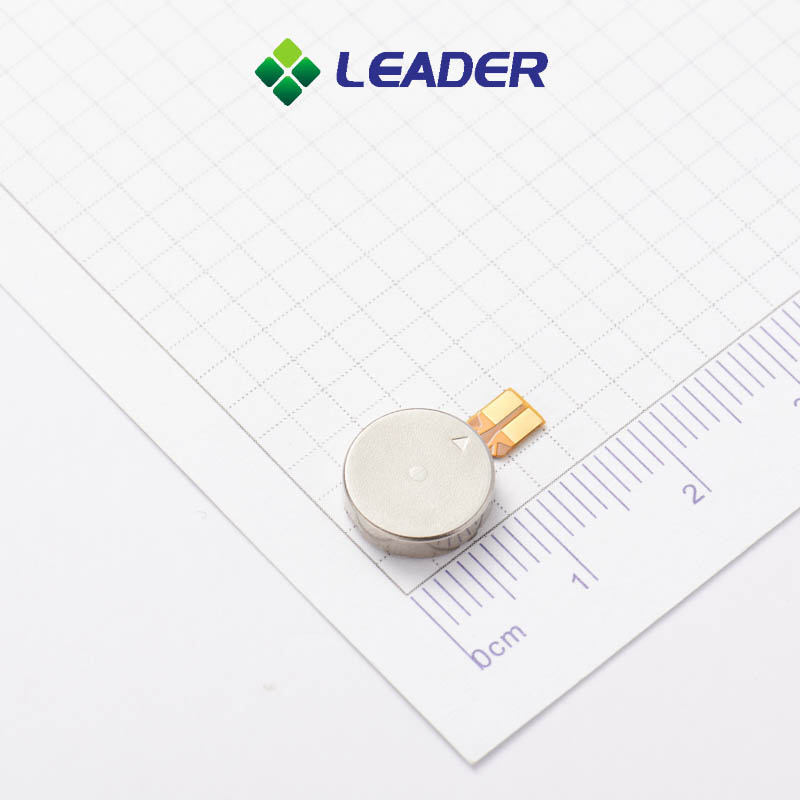

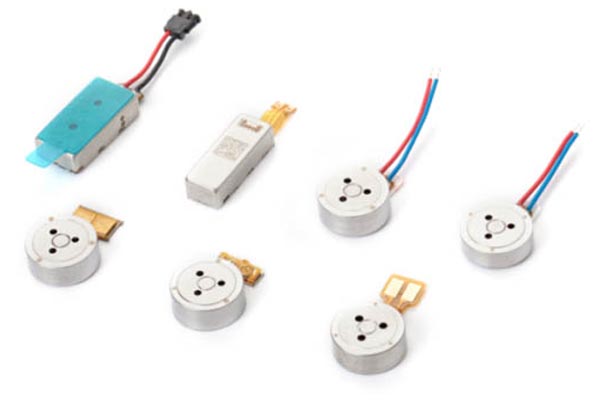

FPCB Type

Coin Vibration Motor Datasheet

The coin vibration motor of 7mm diameter flat vibration motor, 8mm, 10mm vibration motor to dia 12mm has various models and choices, and with highly automated and low labor cost. These coin type vibration motor is widely used in various consumer electronic products with high cost performance.

| Models | Size(mm) | Rated Voltage(V) | Rated Current (mA) | Rated(RPM) | Voltage(V) |

| LCM0720 | φ7*2.0mm | 3.0V DC | 85mA Max | 13000±3000 | DC2.5-3.3V |

| LCM0820 | φ8*2.0mm | 3.0V DC | 85mA Max | 15000±3000 | DC2.5-3.3V |

| LCM0825 | φ8*2.5mm | 3.0V DC | 85mA Max | 13000±3000 | DC2.5-3.3V |

| LCM0827 | φ8*2.7mm | 3.0V DC | 85mA Max | 13000±3000 | DC2.5-3.3V |

| LCM0830 | φ8*3.0mm | 3.0V DC | 85mA Max | 13000±3000 | DC2.5-3.3V |

| LCM0834 | φ8*3.4mm | 3.0V DC | 85mA Max | 13000±3000 | DC2.5-3.3V |

| LCM1020 | φ10*2.0mm | 3.0V DC | 85mA Max | 13000±3000 | DC2.5-3.3V |

| LCM1027 | φ10*2.7mm | 3.0V DC | 85mA Max | 13000±3000 | DC2.5-3.3V |

| LCM1030 | φ10*3.0mm | 3.0V DC | 85mA Max | 13000±3000 | DC2.5-3.3V |

| LCM1034 | φ10*3.4mm | 3.0V DC | 85mA Max | 13000±3000 | DC2.5-3.3V |

| LCM1234 | φ12*3.4mm | 3.0V DC | 100mA Max | 11000±3000 | DC3.0-4.0V |

Vibration Motor Flat Coin Details

| Rated Voltage: | 3.0 VDC |

| Operating Voltage: | 2.7 ~ 3.3 VDC |

| Rated Current: | Max 80mA @ Rated Voltage |

| Operating Temp Range: | -20 °C ~ +60 °C |

| Mechanical Noise: | 50 dB(A) Max |

| Rated Speed: | Min 10,000 RPM @ Rated Voltage |

| Rotation: | CW and CCW |

Please read the precautions in our specifications carefully before using the haptic feedback motor. It is suggested to use the motors within 6 months as possible as you can. If you have issues with your order, please contact our sales manager at leader@leader-cn.cn

You will be responsible for all the local taxes and custom duty.

Return shipping will be paid by the customers.

Although integrating a small vibrating motor into your application may seem simple, achieving reliable mass production may be more challenging than expected.

It is critical to consider a variety factors of small vibrating motors , including:

Vibration amplitude and frequency,

Motor winding tuning of the power supply,

Audible noise levels,

Motor life,

Tactile response characteristics,

EMI/EMC electrical noise suppression,

With our manufacturing and volume production, we can take care of this aspect so that you can focus on enhancing the value-added functionality of your application

Get A Quote Within 8 Hours Contact Now! Any question about Miniature Coin Motor, Spec, Data-Sheet, Quote…

If you want a custom lead wire connection for the flat vibration motors. Such as alternate lead wire length & strip lengths, with a connector (e.g. Molex, JST). You can contact us from the footer form, and tell us your need.

Any problems will be taken seriously and will be answered professionally, so pls do not hesitate to contact us by the footer form.

As a reputable manufacturer, we prioritize quality and customer satisfaction. Our state-of-the-art production facilities and stringent quality control processes ensure that every Coin Vibration Motor we produce meets the highest industry standards.

Get in Touch with Us

Ready to place an order or need more information? Contact our team today to learn more about our Coin Vibration Motors and how we can support your business needs. Request a quote now and experience the quality and reliability of our products firsthand.

Key Features of Our Flat Vibration Motors:

Using for touch feedback wearables, mobile phones, and scanners. The motor should be compact, and easy to install in haptic feedback applications. They produce minimal noise during vibration. It should be able to replace buttons and operate at 3V DC, providing a low-power vibration alarm solution. Furthermore, it rotates in both clockwise and counterclockwise directions. Disc vibration motor is cost-effective for both prototyping and mass production.

Flat Coin Vibration Motor Application Ideas:

Coin vibration motors are versatile and found in a variety of applications including smartwatches, fitness trackers, and other wearable devices. They are particularly popular due to their small size and enclosed vibration mechanism. These electrical vibration motor provide discreet alerts, precise alarms and tactile feedback to enhance the user experience.

—Smartphones, to provide haptic feedback for notifications, calls, and other events. 8mm phone vibration motor can also be used to enhance the tactile feedback of buttons or virtual buttons on the screen.

—Wearable devices, such as smartwatches and fitness trackers to provide haptic feedback for notifications, calls, and activity tracking. They can also be used to enhance the user experience with touch-based controls.

— E-cigarette, by attaching the motor, it can provide tactile feedback to users.When the user activates or deactivates the device, the vibrator motors generates a vibration effect that provides haptic feedback to the user.In addition, the motor can also generate a vibration during inhalation, which can enhance the overall experience of using the electronic cigarette. This vibration effect can create a sense of satisfaction that is similar to the sensation of smoking a traditional cigarette.

—Eye masks, to provide gentle massaging and relaxation through vibrations. They can also be used to enhance the experience of meditation or relaxation techniques by providing soothing vibrations to the eyes and head.

- Video Game Controllers: Enhance the gaming experience by adding vibration feedback to simulate a variety of in-game events such as explosions, collisions, and motion.

- User input feedback: Provides tactile feedback to users when they interact with touch screens, buttons, or other control interfaces, validating their input and enhancing the overall user experience.

-Touch Sensory Feedback: Create a more immersive and realistic experience in virtual or augmented reality applications by incorporating tactile feedback that simulates when a user interacts with a virtual object or surface.

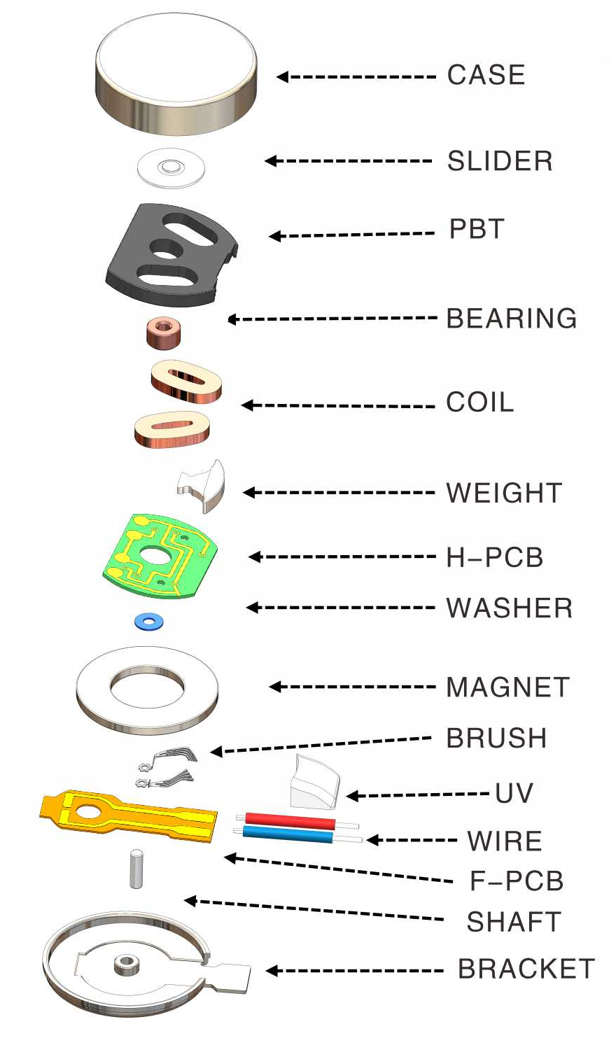

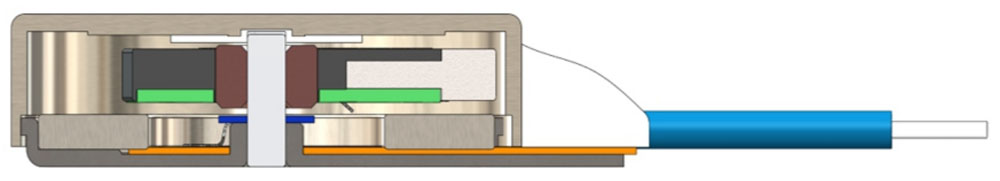

The Structure And Working Principle of ERM Motors

Coin vibration motors (also known as ERM motors) generally have a disc-shaped housing made of metal, with a small motor inside that drives an eccentric weight. Here are the general steps of how a coin vibration motor operates:

1. Power On: When power is applied to the motor, an electrical current flows through the coils inside, creating a magnetic field.

2. Attraction Phase: The magnetic field causes the rotor (eccentric weight) to be attracted towards the stator (coil). This attraction phase moves the rotor closer to the magnetic field, building up potential energy.

3. Repulsion Phase: The magnetic field then switches polarity, causing the rotor to be repelled from the stator. This repulsion phase releases the potential energy, causing the rotor to move away from the stator and rotate.

4. Repeat: The erm motor repeats this attraction and repulsion phase several times per second, causing rapid rotation of the eccentric weight. This rotation creates a vibration that can be felt by the user.

The speed and strength of the vibration can be controlled by varying the voltage or frequency of the electrical signal applied to the motor. Coin vibration motors are commonly used in devices that require haptic feedback, such as smartphones, gaming controllers, and wearables. They can also be used for alert signals, like notifications, alarms, and reminders.

Start Voltages

The start voltage and drive signals for a coin vibration motor can vary depending on the specific motor and the desired vibration strength. The start voltage for coin vibration motors typically ranges from 2.3V to 3.7V. This is the minimum voltage required to initiate the motor movement and vibration.

However, if the start voltage is too low, the motor may not start or may start slowly, resulting in weak vibration. This can cause the device to function improperly or not at all and may lead to user dissatisfaction. If the start voltage is too high, the motor may start too quickly and with too much force, causing damage to the internal components. This can also lead to a reduced lifespan and may cause additional problems such as excessive heat or noise.

Therefore, it's important to ensure that the start voltage is within the LEADER's recommended operating range and to avoid using voltages too high or too low. This can help to ensure proper motor operation, optimal vibration strength, and maximum lifespan.

Why Are Coin Motors Easy to Install?

The miniature coin motor is equipped with self-adhesive tape on the front or back of the motor body, which can be securely connected to the PCB or product housing. Additionally, each type of vibration motor is available with a variety of contact options, including lead wire, connector, FPC and spring types, providing flexibility for your specific needs.

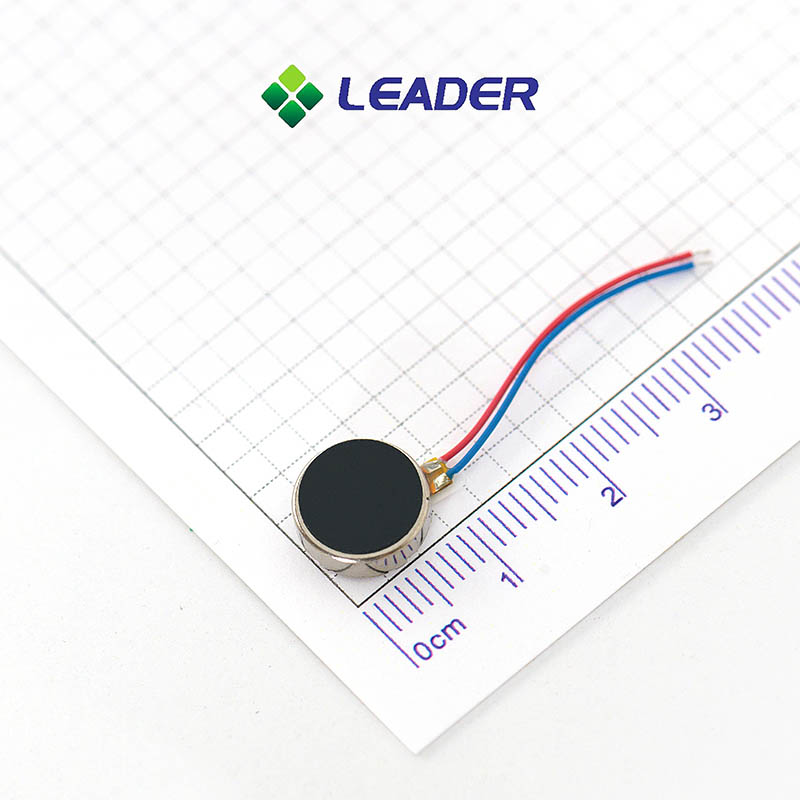

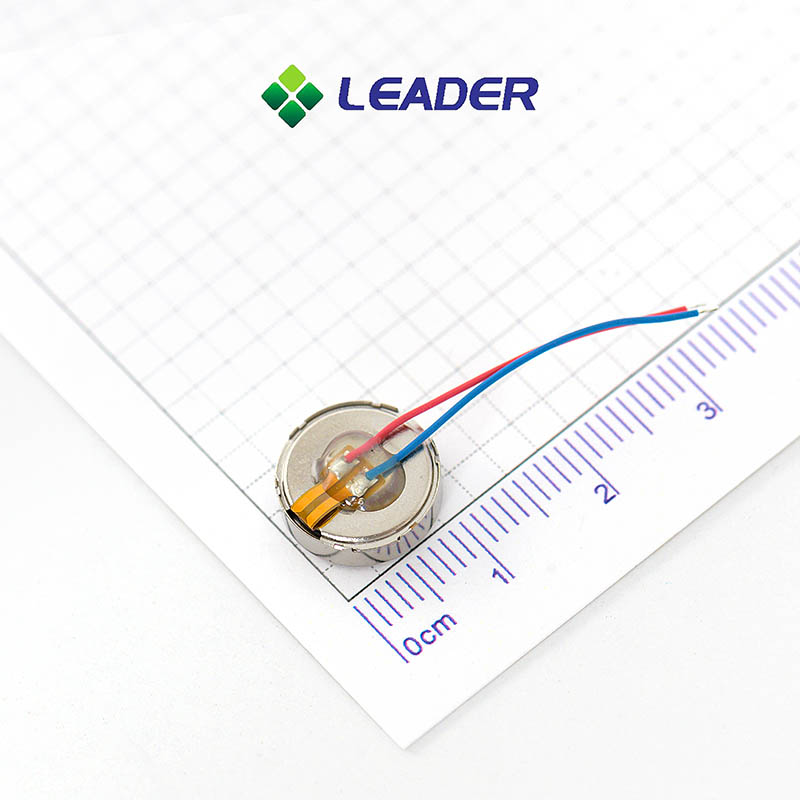

1. Lead Wire: The coin motor can be connected to a power source through two wire leads. This type of wire uses imported wire (Sumitomo), which is made of halogen-free and Eco-friendly material. The wire leads are typically soldered to the motor terminals, and then connected to the power source by terminals or connectors. This method provides a simple and reliable connection, but may require additional space for the wire routing.

2. Connector: Many coin vibration motors have a mating connector that can be used for easy installation and removal. The connector provides a secure and repeatable connection that does not require soldering. However, this method may add cost.

3. Flexible Printed Circuit Board (FPCB): An FPCB is a thin and flexible circuit board with conductive traces that can be used to connect the motor to other components or circuits. This method provides a compact and low-profile solution for installing the motor, and also allows for customization of the circuit layout. However, it may require specialized manufacturing processes and can be more expensive than the lead wire type.

4. Spring Contacts: Some coin vibration motors come with spring contacts that can be used to make a temporary or semi-permanent connection. The spring contacts provide a low-cost and simple installation method that does not require soldering or wires. However, they may not be as secure or reliable as other methods, and may require additional mechanical support.

The choice of installation method will depend on the specific requirements of the application, including space limitations, vibration strength, and ease of installation and maintenance. LEADER's technical experts will provide professional advice based on their project experience during the customer's design phase.

LEADER Coin Vibration Motors Development History

At begining , we produce normal coin vibrating motors(brush coin) inclues 0820, 0830, 1020, 1027 with lead wire models. LCM0820 is always the most popular product with high cost performance.

From 2016, we produce 0820 FPC type vibration motors with big vibration & fast response. Then we produce the smallest coin brush motor in the world of LCM0720.

From 2021 a new type of coin vibration motor came out, called brushless DC coin motor with long life time, big vibration and quick feedback. There are 3 models, LBM0620, LBM0625 and LBM0825.

In 2023, we developed the smallest brushless pancake vibration motor LBM0525.

Leader motor can all connect with FPC terminals for very easy and flexible PCB assembly. These models are widely used in wearable devices. Monthly capacity: 5 million pieces.

It is important to provide the following information: dimensions, application, desired speed and voltage. Additionally, providing application prototype drawings (if available) helps ensure accurate customization of the micro vibrating motor and we can provide vibration motor datasheet asap.

Our main products are coin vibration motor, linear vibration motor, brushless vibration motor and coreless motor.

Yes, we offer free sample of the electrical vibration motor. Please contact us for more details on how to proceed.

You can choose multiple payment methods, such as T/T (bank transfer) or PayPal. If you wish to use an alternative payment method, please contact us in advance to discuss available options.

Air shipping / DHL / FedEx / UPS with 3-5 days. Sea shipping with about 25 days.

FAQ For Coin Vibration Motors

Yes, coin vibration motors can be customized to meet specific performance or size requirements for different applications. Customization options of coin motors may include different vibration strengths, operating voltages or frequencies, or housing materials.

The vibration strength of a flat motor can be measured in terms of G-force, which is the amount of gravitational force exerted on an object. Different eccentric rotating mass motor may have different vibration strengths measured in G-force, and it's important to choose the appropriate motor for the specific application.

The waterproofness of coin vibration motors can vary, depending on the specific model and manufacturer. Some eccentric rotating mass vibration motor may be designed for use in wet or humid environments, while others are not. If required, we can add a waterproof cover according to the specific needs of your project.

Choosing the right coin vibration motor depends on several factors, including the size and thickness of the device, the required vibration strength, and the power consumption requirements. It's important to consult with LEADER for specific recommendations and testing before making a final selection of small pancake motor.

A coin vibration motor and a linear vibration motor are two different types of motors used for vibration. A coin motor typically consists of a rotating offset weight that creates an unbalanced force to produce vibration, while a linear motor consists of a moving mass that oscillates along a linear path to produce vibration. Linear motors are AC- driven and require additional driver IC. However, coin motors are easier to drive by supplying DC power according to the voltage range recommended in the specification.

Vibration motors, also known as haptic motors, are commonly used in wearable devices such as smartwatches and fitness trackers to provide users with tactile feedback.

These motors work by converting electrical energy into mechanical vibrations that can be felt. The mechanism behind vibrating motors involves an unbalanced mass attached to the motor shaft. As the motor rotates, the unbalanced mass causes the motor to vibrate. This vibration is then transmitted to the wearable device, allowing the user to feel it.

To control the vibration motor, a drive circuit is usually used. The drive circuit regulates the amount and frequency of electrical energy supplied to the motor, allowing the intensity and pattern of vibration to be adjusted. This allows for different types of feedback sensations, such as a slight vibration or a stronger buzz.

In wearable devices, vibration motors are often used to provide notifications, alerts, and alerts. For example, a smartwatch can vibrate to notify the wearer of incoming calls or messages. The vibration motor also provides tactile feedback during exercise, helping users track their fitness goals.

Overall, vibration motors are crucial in wearable devices as they provide tactile feedback, enhance the user experience and keep the wearer connected and engaged with their device.

Typically this is around 2.3v (all coin vibration motors have a nominal voltage of 3v), and failure to respect this could result in motors not starting when the application is lying in certain orientations.

Our coin types vibration motor have 3 types, brushless types, ERM eccentric rotating mass type, LRA linear resonant actuator type. Their shape is a flat coin button-type.

The commutation circuit alternates the direction of the field through the voice coils, and this interacts with the N-S pole pairs that are built into the neodymium magnet. The disc rotates and, due to the built-in off-centred eccentric mass, the motor vibrates!