Ultrasonic Motors DC 3.6V Toothbrush Vibrating Motor

A sonic vibration motor, also known as an ultrasonic motor, is a device that utilizes acoustic vibrations to achieve energy conversion and drive.

Sonic vibration motor is a new kind of drive device, which is different from the traditional electromagnetic motor, but based on the characteristics of piezoelectric material, utilizing the ultrasonic vibration energy converted into rotational energy.

This unique driving method makes the sonic motor widely used in many fields, especially in the occasions that require high acceleration, low wear and tear, low noise and special environment.

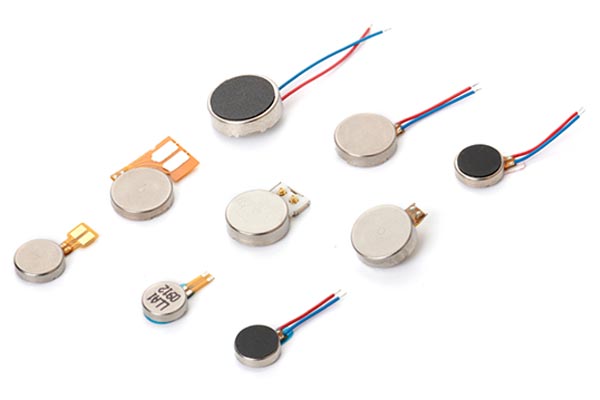

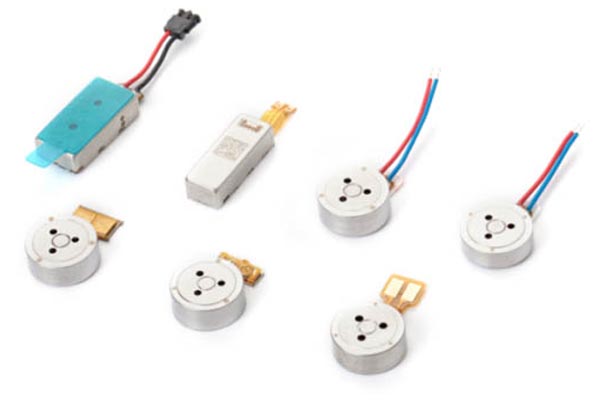

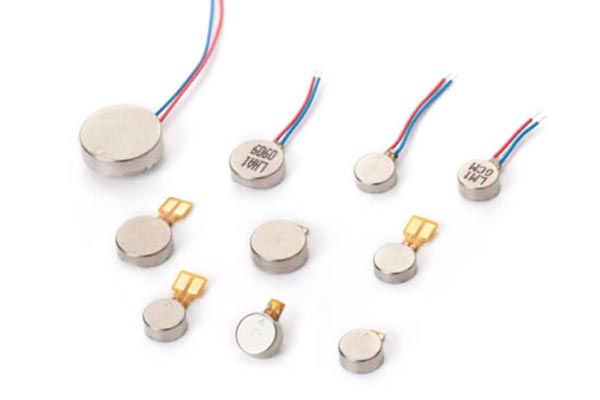

What We Produce

| Model | Size(mm) |

Rated Voltage(V) |

Rated Current (mA) | Rated Speed(RPM) | Range(V) |

| LDSM1238 | 12*9.6*73.2 | 3.6V AC | 450±20% | 260HZ | 3.0-4.5V AC |

| LDSM1538 | 15*11.3*73.9 | 3.6V AC | 300±20% | 260HZ | 3.0-4.5V AC |

| LDSM1638 | 16*12*72.7 | 3.6V AC | 200±20% | 260HZ | 3.0-4.5V AC |

Still not finding what you're looking for? Contact our consultants for more available products.

Sonic Vibration Motor Driving Principle

Sonic vibration motors work primarily by utilizing the properties of piezoelectric materials. When a voltage is applied to these materials, they deform. This deformation is mechanically vibrated at ultrasonic frequencies. These ultrasonic vibrations are converted into rotary motion or linear movement by means of a specific friction drive mechanism design.

Product Features (Sonic motors have the following advantages over traditional electric motors).

The vibration frequency of the acoustic motor is designed to be outside the range of what the human ear can hear, making it virtually silent during operation. Ideal for applications that require a low noise environment.

Because the sonic motor works on a different principle than traditional electromagnetic motors, it can generate very high acceleration and deceleration, giving it a unique advantage in certain specific applications.

Since there is no mechanical contact between the stator and the actuator of the sonic motor, the mechanical wear and tear is very low, which greatly extends the service life of the product.

The simple structure of the sonic motor makes its maintenance and overhaul very convenient. At the same time, due to its unique driving method, the replacement of the motor also becomes very easy.

Sonic motors are suitable for use in a variety of harsh environments, extremely clean and non-polluting environments, as well as in areas of special need, such as camera lenses, medical equipment, aerospace and so on.

Principles of Sonic Vibration Motors in Electric Toothbrushes

In electric toothbrushes, the sonic motor works by generating high-frequency vibrations in piezoelectric ceramics driven by electrical energy. This vibration is transmitted to the brush head, causing the bristles to make rapid, tiny displacements, resulting in a sonic-level cleaning effect.

The vibration characteristics of an electric toothbrush are determined by the frequency and amplitude of the sonic motor. High-frequency vibration is used to drive the bristles in a rapid reciprocating motion, thus realizing an efficient cleaning effect. High-frequency vibration can effectively mix toothpaste and water to form a rich foam, which can better penetrate into the crevices and all corners of the mouth. On the other hand, high-frequency vibrations move the bristles quickly and minutely, effectively removing plaque and food debris. This principle is usually realized by the built-in sonic motor and vibration device.

The acoustic motor is the core component that generates the high-frequency vibrations, while the vibration unit is responsible for transmitting the vibrations to the bristles. In general, the higher the frequency of the vibrations, the better the cleaning effect. The amplitude of the vibration determines the force of the bristles on the surface of the teeth. Excessive amplitude can lead to tooth damage and therefore needs to be controlled.

The application of sonic motors in electric toothbrushes not only improves the cleaning effect, but also improves the user experience and oral health. The low noise design makes it more comfortable for the user. High-frequency vibration can better remove plaque and prevent oral diseases. In addition, sonic electric toothbrushes are usually equipped with a variety of brushing modes to meet the individual needs of different users.

Looking for more innovations in wearable tech for kids? Discover how our vibration motors for kids' watches offer fun and engaging feedback.

Get Micro Brushless Motors in Bulk Step-by-step

We help you avoid the pitfalls to deliver the quality and value your micro vibration motors need, on-time and on budget.